A look at the core component that accounts for the highest cost share of humanoid robots: the reducer

In humanoid robots, the gearbox is the core component of the robot's mechanical system, usually occupying 30% of the overall machine cost.The main function of the gearbox is to match the rotational speed between the prime mover (e.g., motor) and the working mechanism (e.g., the robot's joints), and to transfer torque efficiently. Its structure consists of a number of gears that mesh together to reduce the rotational speed and increase the output torque by means of gears of different sizes.

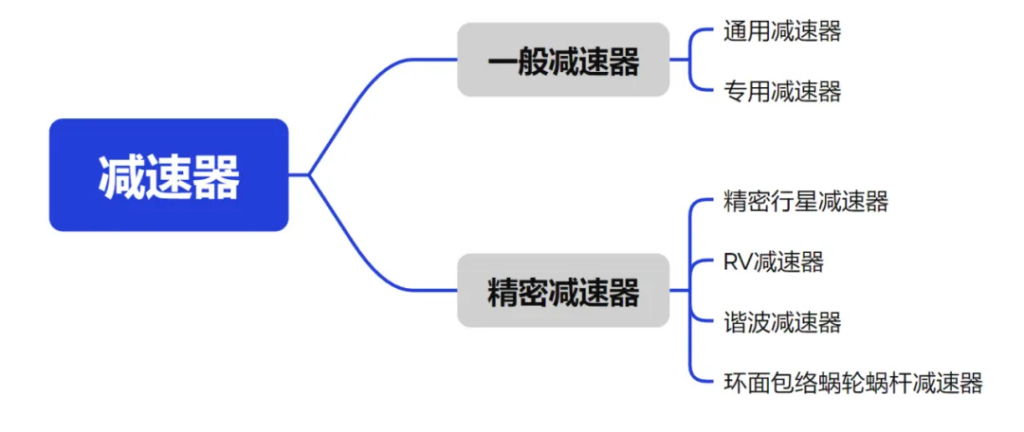

Reducer type

Reducer can be divided into two categories according to the accuracy of the general drive reducer and precision reducer. The general drive reducer can be subdivided into general-purpose reducer and special reducer, while the precision reducer includes precision planetary reducer, harmonic reducer, RV reducer, ring surface envelope worm gear reducer and so on.

I. Precision Planetary Reducer

Of the four main types of precision gearboxes, planetary gearboxes have the longest history of development. As early as the 1880s, the first patent for a planetary gear unit appeared in Germany, marking the beginning of this technology. Into the 1920s, the planetary gearing device for the first time to achieve mass production, opened up the era of widespread application. China has been developing and applying planetary gearboxes since the 1960s, and after years of development, domestic head enterprises such as Kefeng Intelligence, Zhongda Lidu, and Nu's Dart were generally established at the beginning of the 21st century, which has promoted the innovation and progress in this field. These enterprises not only inherited the traditional advantages of planetary gearboxes, but also continue to make technological breakthroughs, injecting new vitality into the development of the industry.

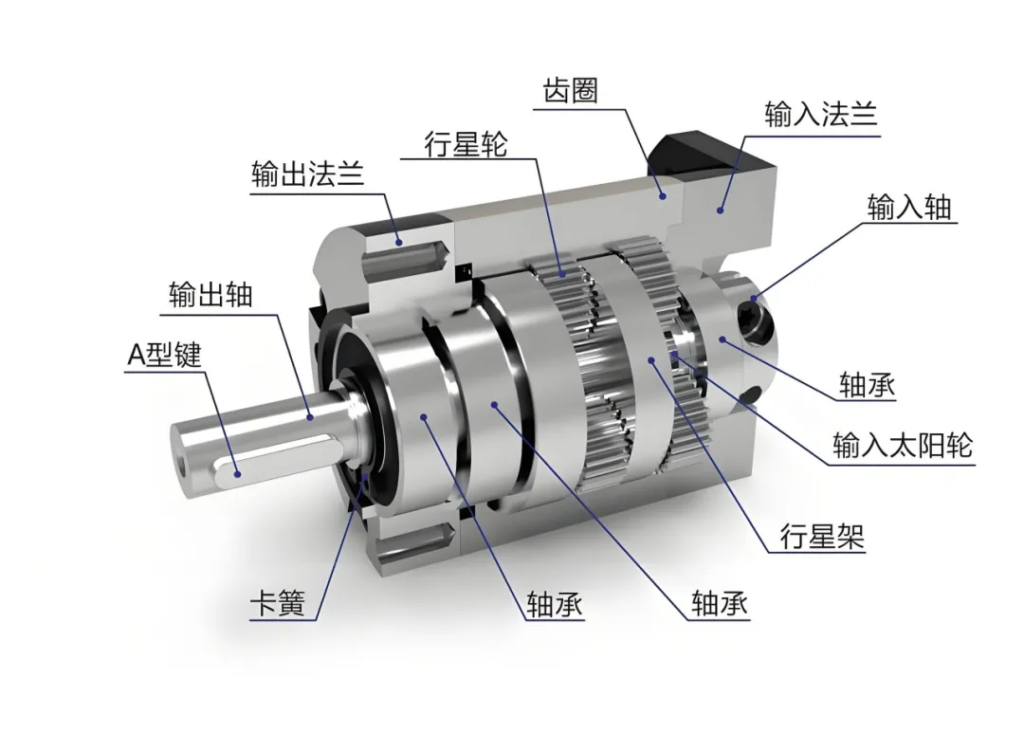

Working Principle

The planetary reducer is based on the gearing principle and its structure includes a sun wheel, a planetary wheel, an internal gear ring and a planetary carrier. The sun wheel is connected to the motor, the planetary wheel rotates around the sun wheel, and the torque is transmitted through the planetary carrier. Simple structure and high transmission efficiency, mostly installed in the servo motor, used to reduce speed, improve torque, precise positioning, which is often used in the robot for low precision requirements of the part of the body rotary joint.

Structural characteristics

Small size and light weight: the combination of precision design and manufacturing process reduces the size and weight.

High transmission efficiency: symmetrical structure makes single-stage transmission efficiency up to 97-98%.

Strong Load Carrying Capacity: Multiple planetary wheels share the load to increase the load carrying capacity.

Excellent impact resistance: inertial balance for smoother movement.

Simple structure: lower cost compared to harmonic, RV reducers, ring-enveloped worm gear reducers.

inferior

Single-stage reduction ratios are small, typically between 3 and 10. Multi-stage reduction increases length and weight.

Regular maintenance and servicing is required, including changing lubricants and repairing drive components.

Precision is relatively inferior to other types of reducers, and high precision requirements increase manufacturing costs.

★ Typical companies ★

| corporations | summary |

| Middle Hercules (English translation) | Founded in 2006, with outstanding technical strength, Zhongdaide successfully produced servo precision planetary gearboxes in 2008, and again led the industry by launching the first servo helical gear high-precision planetary gearboxes in 2011. As the only enterprise in China that provides precision gearboxes (including precision planetary gearboxes, RV gearboxes and harmonic gearboxes), servo drives, permanent magnet DC motors and AC geared motors at the same time, ZHONGLI DUODE has developed an integrated product solution of "Harmonic gearboxes/RV gearboxes/precision planetary gearboxes+servo motors + drives" to meet the diversified market demands. solutions to meet the diversified market demand. |

| Newstadt (name) | Established in 2006, Newstat is well known for its cost-effective planetary gearbox products. Newstar's products are widely adapted to servo motors from well-known manufacturers such as Yaskawa, Panasonic, Mitsubishi, Fuji in Japan and TECO in Taiwan, making them a trusted choice in the industry. |

| Kefeng Intelligence | Its controllers started the research and development of planetary gearboxes in 2004, and officially founded KeFeng Intelligence in 2010, and realized the production of planetary gearboxes in 2016. KeFeng Intelligence specializes in planetary gearboxes, harmonic gearboxes, planetary ballscrews and mechatronic products, and is committed to providing customers with high-performance solutions. |

| Fengli Intelligence | Founded in 1995, it is a leading company in the field of small modulus gears. The main products of Fengli Intelligent include steel gears, precision reducers and parts, precision mechanical parts, powder metallurgy products and pneumatic tools, covering the production of planetary reducers and harmonic reducers with strong strength. |

II. RV Reducer

Fully known as Rotary Vector (RV) gearbox, it is a high precision mechanical transmission device, first invented in Japan. It is designed to achieve high torque output and high precision rotary motion, and is usually widely used in heavy load positions such as robot bases, arms, and shoulders.

The history of RV gearboxes can be traced back to 1926, when Lorenz Blanc of Germany first introduced the concept of needle-oscillating planetary drives. Since then, this technology has been introduced by Sumitomo and successfully used in the development of pendulum grinders. In 1980, Teijin Seiki further put forward the theory of RV transmission, and realized the official mass production of RV gearbox in 1986. 1960s, needle-pendulum transmission technology was introduced into China, and by the end of the 80s, China began to research on the theory of RV. 2010, with the intervention of domestic manufacturers such as Shuanghuan Transmission and Zhongda Lidu, the market monopoly of overseas brands has been gradually broken. market monopoly of overseas brands.

Although RV gearboxes show excellent performance in many fields, due to their complex structure and numerous parts, the manufacturing process faces more constraints, which makes the market share of domestic RV gearboxes relatively low and the development speed relatively slow. At present, Japan's Nabtesco is the world's largest RV reducer manufacturer, while domestic brands such as Shuanghuan Drive, Zhuhai Pegasus and Zhongda LiDe are steadily developing and gradually improving their competitiveness in the market.

Working Principle

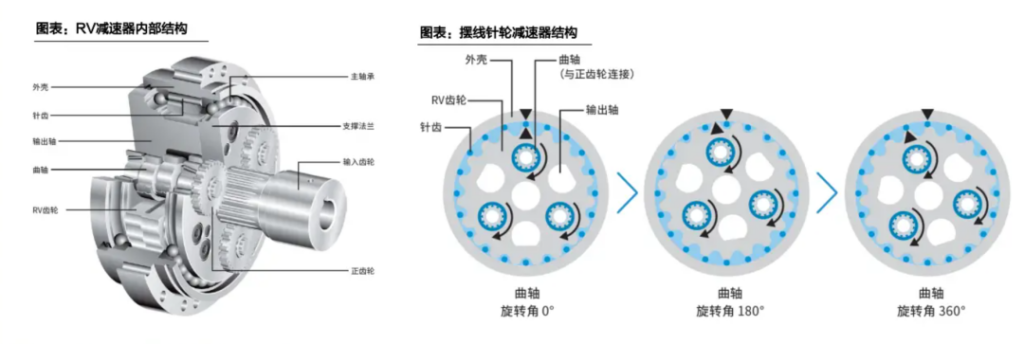

RV gearboxes usually consist of a two-stage reduction mechanism, where the first stage is a spur gear reduction mechanism and the second stage is a differential gear reduction mechanism.

Its operating principle combines the two core concepts of spur gear speed change and differential gear speed change. Through the cooperation between the planetary wheel and the sun wheel, the gear realizes an efficient speed change function, while the precise meshing between the RV gear and the needle wheel further enhances the deceleration effect. This compound transmission mechanism not only enhances torque output, but also ensures high precision and stability of movement.

Structural characteristics

Wide range of transmission ratios: RV gearboxes are able to provide diversified transmission ratios to flexibly meet the needs of different application scenarios, with strong adaptability.

Long life and high precision: thanks to the large number of gears meshing simultaneously, the RV reducer shows excellent rigidity and resistance to overload, ensuring that its transmission precision remains stable over a long period of time and extending the overall service life of the equipment.

Efficient transmission and smooth operation: With its symmetrical structure and precision design, RV reducer not only has high transmission efficiency, but also can effectively control vibration and realize smooth operation effect.

inferior

Larger size: In order to achieve a high torque transmission capacity, RV gearboxes have a high number of gears and ancillary components (such as bearings, lubrication systems and seals), which makes their overall size relatively large.

Higher manufacturing costs: The production process of RV gearboxes is complex, relying on high-precision machining processes and special manufacturing equipment. This not only increases the complexity of production and assembly and extends the manufacturing cycle, but also leads to an increase in overall manufacturing costs.

★ Typical companies ★

| corporations | summary |

| Nabtesco (city in Germany) | As a leader in the RV gearbox industry, Nabtesco has had an illustrious history in this field for more than 20 years. Its products are known for their high precision and rigidity, as well as their small size and light weight, making them the first choice for many high-end applications. |

| Sumitomo, Japanese company | Sumitomo Drive Technologies, a core business unit of Sumitomo Heavy Industries, Ltd. has established more than 250 offices in more than 50 countries around the world, and has become a leader in the field of power transmission and control systems, and continues to lead the industry with its outstanding technological capabilities. |

| Double Ring Drive | Founded in 1980, Shuanghuan Drive specializes in the production and sales of gears and their components, and has become a leading enterprise in the domestic gear industry. Since 2013, Shuanghuan has set up a team of high-precision gearboxes and realized a batch listing in 2016. Relying on its profound accumulation of gear technology, Shuanghuan has continued to research and develop RV gearboxes and harmonic gearboxes, and constructed a full series of product lines suitable for industrial robots. |

| Nantong Zhenkang | Nantong Zhenkang, which specializes in high-precision industrial robots and precision automation products such as welding wire feeding device and RV reducer, has been developing RV reducer since 2010 and realized the first batch of production in 2015, and is committed to providing customers with high-quality automation solutions. |

| Middle Hercules (English translation) | Founded in 2006, Zhongda Leader successfully developed precision planetary reducer for servo in 2008 and launched the first helical gear high-precision planetary reducer for servo in 2011. As the only company in China that provides precision gearboxes (including precision planetary gearboxes, RV gearboxes, harmonic gearboxes), servo drives and permanent magnet DC motors, AC gear motors at the same time, ZHONGDAID is committed to creating an integrated product solution. |

| Qinchuan machine tool | Qinchuan Machine Tool, which specializes in machine tools, firmly focuses on the high-end speed reducer market. By the end of 2021, the production and sales volume of its RV reducers exceeded 30,000 units, occupying 20%-25% share of the domestic market. By May 2023, the production capacity of its articulated reducers has reached 60,000-90,000 sets, while the R&D and trial production of harmonic reducers are also accelerating. |

III. Harmonic Reducer

Harmonic reducer is an excellent high-precision mechanical transmission device, relying on three core components, namely special waveform generator, flexible spline (flex wheel) and rigid spline (rigid wheel), to skillfully realize efficient transmission of motion and power. Its small size, light weight, and simple and compact structure make it excel in high reduction ratio, zero backlash, high torque density, accuracy and reliability. Because of this, harmonic reducers are widely used in robot arms, wrists and hands, where size and flexibility are critical.

The history of harmonic transmission can be traced back to 1955, which was firstly proposed by the American inventor C.W. Musser.In 1964, Japan introduced this advanced harmonic gearing technology, and it was formally commercialized in 1970.In 1961, the harmonic transmission technology was introduced into China, and after unremitting efforts, the first harmonic speed reducer was successfully developed in China in 1962.In 2003, the The domestic enterprises led by Green's harmonic began to start research and development, and gradually realized the industrialization process.

At present, the global harmonic speed reducer market shows a highly concentrated state, mainly dominated by Japan's Hamonaco, while Green's Harmonic is one of the representative enterprises in China. With continuous technical innovation and market expansion, these enterprises have contributed to the development and application of harmonic reducer.

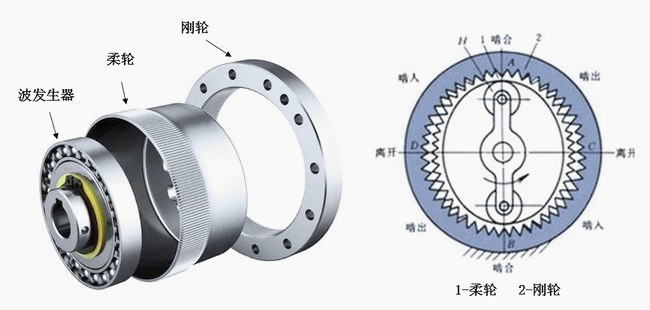

Working Principle

The harmonic reducer works on a very unique and efficient principle. One of its core components, the waveform generator, is elliptical in shape and closely connected to the motor shaft. Through its compact oval hub and specially designed thin-walled bearings, the waveform generator produces controlled elastic deformation waves. These deformation waves are then transmitted to the flexure wheel, which causes a dynamic interaction between the flexure wheel and the rigid wheel, resulting in deceleration and an effective increase in output torque. In this process, the number of teeth on the rigid wheel is designed to be slightly larger than the number of teeth on the flexible wheel, and this low-differential mesh design allows the harmonic reducer to achieve significant ratios while maintaining a small size and light weight.

Structural characteristics

Large speed ratio: compact design, high reduction ratio and high transmission accuracy.

Load capacity: Suitable for light duty, high precision applications.

inferior

Weak load carrying capacity: relative to the RV reducer, its load carrying capacity and service life are lower.

Higher cost: Higher cost but lower than RV gearboxes.

★ Typical companies ★

| corporations | summary |

| Hammarnako (town in Norway) | Founded in 1970, it is the world's leading brand of harmonic gearboxes and ranks in the top tier internationally in many areas of precision, quality, size, temperature rise and torque thanks to its small, highly drive-efficient and high-precision harmonic gearboxes. In addition, Harmonic offers mechatronic products in the form of servo actuators and drives. |

| Nippon Shinbo | It is a brand of Nidec, founded in 2003 and entered the Chinese market in 2015. The company specializes in all kinds of speed reducers, including harmonic reduction division, and is committed to becoming a leading international brand. |

| Green harmonics | In 2011, the company began to devote itself to the research and development of harmonic reducer technology in the field of industrial robots, and after 2019, the company realized batch production, gradually replaced imported products, and successfully listed in 2020, becoming the leading enterprise of domestic harmonic reducer. |

| Middle Hercules (English translation) | Founded in 2006, Zhongdaide produced servo precision planetary reducer in 2008 and launched the first servo high-precision helical gear reducer in 2011. As the only company in China that provides a variety of precision reducers, servo drives, permanent magnet DC motors and AC gear motors at the same time, Zhongda Leader's products have realized the integration of "harmonic reducer/RV reducer/precision planetary reducer+servo motor+drive". |

| rifled nopal | In 2014, we began to introduce harmonic reducers, dedicated to replacing imported products, ensuring consistency with them in terms of external dimensions and connections. |

| Daqo Drive | A subsidiary of Daqo Laser, founded in 2016, has more than 300 harmonic reducers developed independently and a new upgrade of the high-torque series. |

| Fengli Intelligence | Established in 1995, it is a leading manufacturer of small modulus gears, whose main products include steel gears, precision gearboxes and components, etc. It will go public in 2022 and start trial production of harmonic gearbox products in small quantities. |

| Double Ring Drive | Founded in 1980, focusing on the production and sales of gears and components, we set up a team of high-precision gearboxes in 2013, realized batch sales in 2016, and developed a series of RV gearboxes and harmonic gearbox products for industrial robots. |

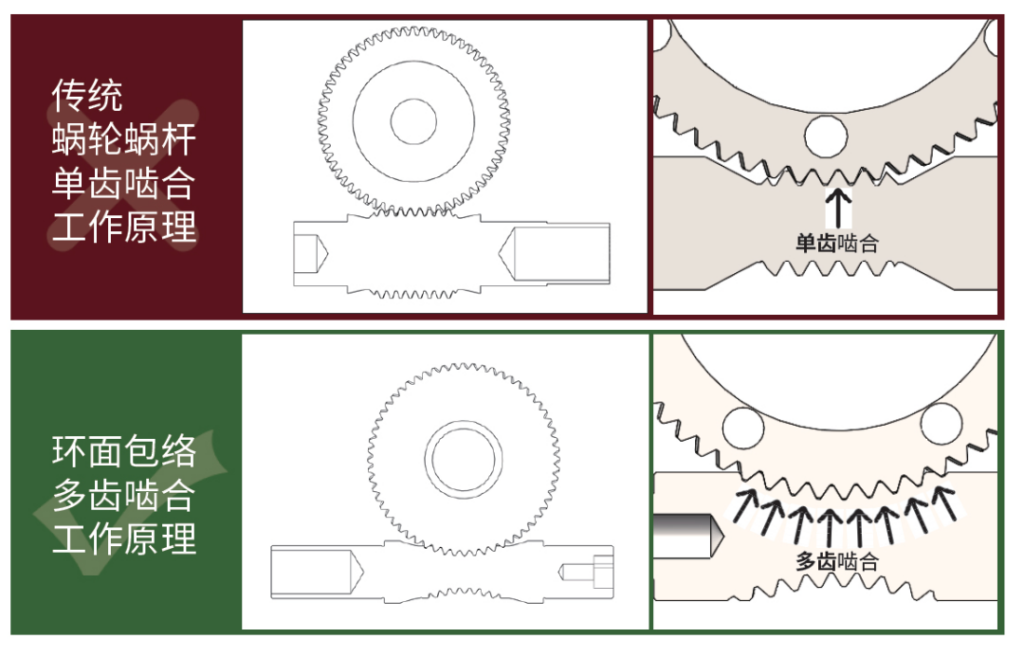

Four, ring surface envelope worm gear reducer

The miniature annular enveloping worm gear reducer uses a worm gear with an annular worm gear to realize the functions of deceleration and torque amplification. The rotation of the worm gear drives the worm wheel to form a high deceleration ratio and high torque output. The design of annular envelope makes the worm and turbine form a multi-tooth meshing state, which greatly improves its load carrying capacity and life.

The history of ring surface envelope worm gear transmission can be traced back to Germany and France in the late 19th century. At that time, the worm gear transmission mainly relied on the proposed circular line and groove structure, which was limited by the processing technology and manufacturing accuracy, resulting in low transmission efficiency and very limited application. With the continuous progress of machining technology and continuous improvement of materials, in the second half of the 20th century, the envelope annulus worm gear transmission gradually came into prominence and became a major form of transmission.

By the 1960s, the famous German enterprise Fagor successfully developed the fully enclosed envelope worm gear drive, which promoted the wide application of this technology in the industrial field. Along with the 21st century robotics boom, the ring surface envelope worm gear transmission technology has ushered in a new opportunity. Dow Intelligent Technology stands out, successfully overcome the miniature ring surface envelope worm gear processing technology, become the world's only one can manufacture miniature ring surface envelope worm gear reducer manufacturers. The smallest size of its products can even reach the size of a knuckle, fully meet the needs of modern high-precision and miniaturization, and promote the development process of robotics and automation equipment.

Working Principle

The working principle of miniature annular envelope worm gear transmission mainly relies on the special meshing mechanism between the worm and the worm wheel. The helical shape of the worm and the groove of the annular worm gear form a unique contact surface, and the rotation of the worm drives the rotation of the worm gear to form an envelope effect, which effectively reduces friction and wear and improves the transmission efficiency. Due to the small pitch design of the worm, the rotation speed of the worm wheel is relatively slow, realizing deceleration and torque increase, which is suitable for high torque and low speed application scenarios. Meanwhile, the miniaturized design enables it to work in a very small space, which is very suitable for modern high-tech products such as robots, precision instruments and automation equipment, thus providing a solid foundation for miniaturization and high-precision applications.

Structural characteristics

Small size and light weight: particularly suitable for space-constrained robot parts such as fingers and small joints.

High Torque Density: Provides high output torque in a small volume for high load applications.

Simple Manufacturing: Relatively few components make the manufacturing and assembly process simpler.

Low cost: Significant cost reduction compared to RV and harmonics.

High precision: its precision can be similar to that of RV and harmonic reducer.

Low noise: its noise decibel ≤ 50dB, much lower than other types of reducer noise.

Long life: Adopting the ring surface envelope design, the life span is 3-5 times higher compared to the single tooth meshing design of the traditional worm gear.

inferior

Relatively low efficiency: possible energy loss due to sliding contact between worm and worm gear.

90° output: naturally forms a right-angle output state, which is a natural advantage in some scenarios; in scenarios requiring 0° output, additional steering is required.

★ Typical companies ★

| corporations | summary |

| Dow Intelligence | Dow Intelligent Technology (Shenzhen) Co., Ltd. is a national high-tech enterprise, formerly known as "Shenzhen Dow Precision Technology Limited", founded in 2016. The unique micro ring surface envelope multi-tooth occlusion high-performance reducer is unique in the world of high-precision reducer field, has won a number of national honors and a number of R & D patents. Currently, Dow's miniature high-performance gearheads are widely used in a variety of high-tech fields such as high-precision industrial automation, aerospace, military, AI artificial intelligence, medical devices, humanoid robots and so on. |

Taoshi Intelligent Technology

Taoshi Intelligent Technology