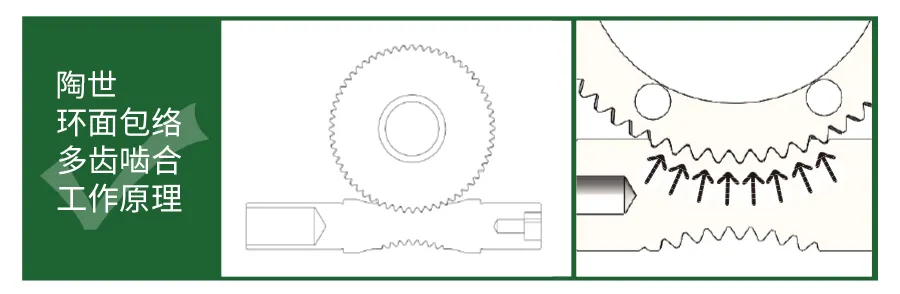

Envelope Worm Gear - Competitive Drive Solutions for the Handy Person

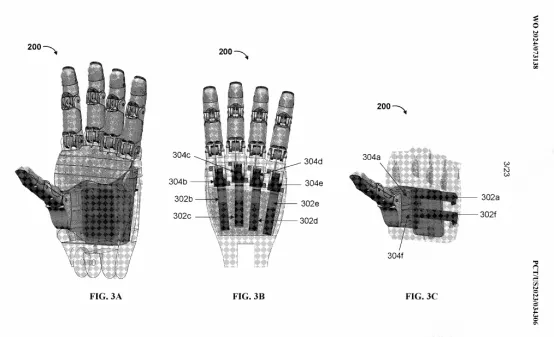

Tesla Dexterity Hand

As industrial automation and artificial intelligence technologies continue to evolve, the role of robots is transforming from single, repetitive task-takers to intelligent beings capable of responding to complex and changing situations. The importance of dexterous hands as a key interaction tool in this evolutionary process has increased.

It enables robots to perform a range of tasks from basic grasping to fine manipulation, thereby significantly broadening their application areas and enhancing their ability to operate in diverse scenarios.

Among them, the dexterous hand of the Tesla optimus robot has attracted attention from all sides. It highly imitates the structure and movement of the human hand, has fine grasping and manipulation capabilities, and can sense object properties through tactile feedback.

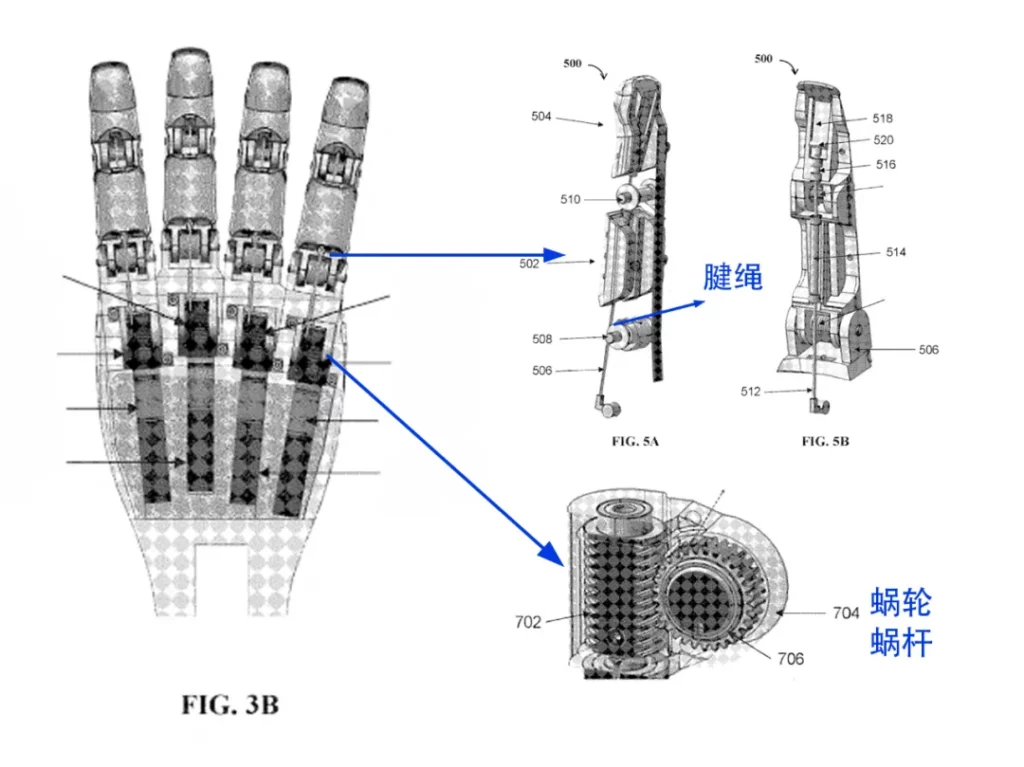

Patent Interpretation

From the dexterous hand patent document published by Tesla, we can see the mechanical design of the optimus robot dexterous hand. It uses a motor-driven worm gear reducer to wind a high-strength tendon rope through a wire wheel at the end of the worm gear shaft to achieve precise motion control of the finger joints.Simply put, the drive is accomplished by a hollow-cup motor, a worm gear knot and a tendon rope.

Among them, the role of the worm gear is to utilize the relative sliding friction between the helical tooth surface of the worm gear and the teeth of the worm wheel to transmit motion and power, while playing a decelerating and locking role.The advantage is its extreme optimization of core requirements such as reduction ratio, self-locking, layout flexibility, and accuracy under extreme space constraints.

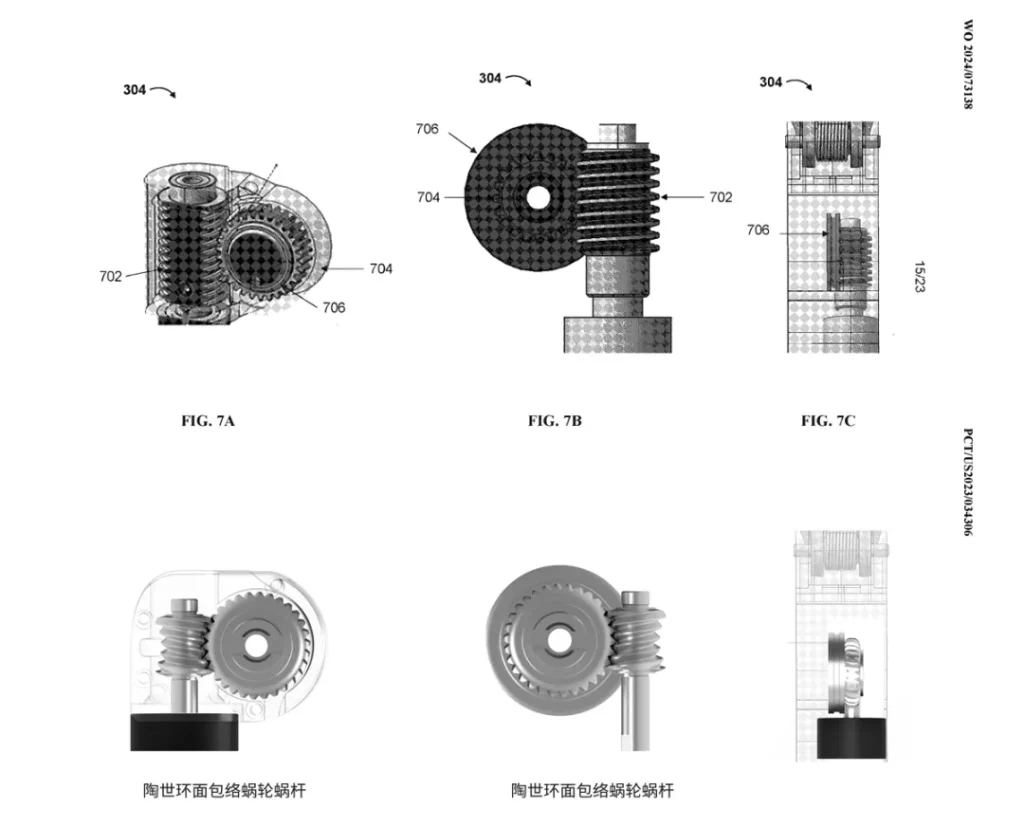

Comparison between Tesla and Taosi worm gear construction

As you can see from the structure diagram, the worm gearbox used by Tesla is a traditional Archimedes worm gear structure. And Taoshi adopts the ring surface envelope worm gear structure, in the case of the same output torque, Taoshi ring surface envelope worm gear structure can beMore compactThe Tausch ring-face enveloped worm gears have the advantage ofHigher torqueThe

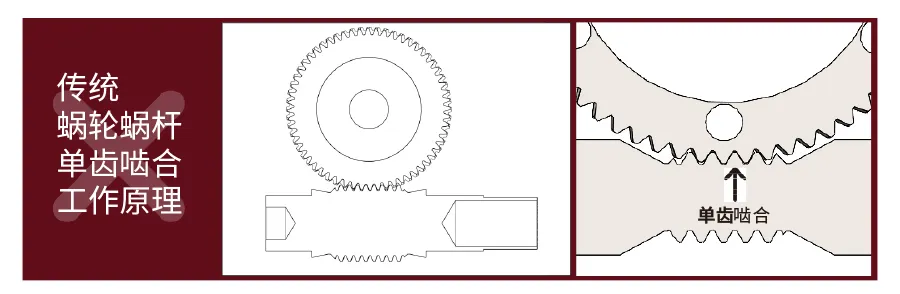

The single-tooth occlusion of the traditional Archimedean worm gear construction is still used today.Inherent limitations::

First, the wheel worm gear single tooth line contact meshing form leads to a high concentration of stress in the root part of the tooth, easy to increase wear;

Second, although Tesla has not publicly disclosed the specific material of the worm gear, but according to the engineering practice, the characteristics of worm gear transmission and Tesla's dexterous hand design goals, we can analyze its material selection probability for tin bronze, or high-performance engineering plastics.

However, the carrying capacity and rigidity of these two are very weak, tin bronze worm gear tensile strength of only 200-250M, such small modulus will also appear in the driveUneven stress, limited load capacity, reduced service life and accuracy retention.

In view of these technical bottlenecks, Tao Shi Intelligent Research and Development of # ring surface envelope worm gear reducer to realize the core breakthrough:

First of all, the unique geometric design of ring surface meshing makes the spiral surface of the worm and the tooth profile of the worm gear form a continuous envelope to realize the synchronous contact of multiple tooth surfaces, and this design bringsRemarkable Advantages–

1. High carrying capacity:Multi-tooth engagement dramatically increases the contact area and effectively spreads the load.

2. Excellent transmission precision:Uniform load distribution ensures a smooth transmission process and significantly reduces transmission errors.

3. Extended service life:Reduces localized stress concentrations and wear, improving overall durability.

Ring Envelope Worm Gear vs. Ordinary Worm Gear

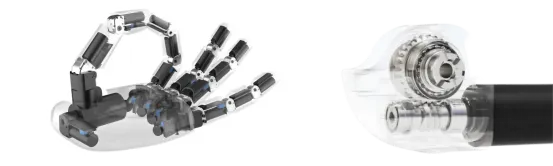

Secondly, the material system is fully upgraded. Taoshi worm gears and worm gears are made of special steel material, and the shell is made of 7075 aviation aluminum material, which reduces the weight by more than 30%, improves the bearing capacity by more than 100%, and the tensile strength is increased to 1,300MPa, which significantly improves the anti-wear ability as well as the service life while maintaining the self-locking characteristics. And with the dexterous hand of Taoshi ring surface enveloping worm gear reducer module, 20 degrees of freedom of direct drive can be realized.

Eventually, in the scenario validation, the solution demonstrated significant advantages:

In the test, the accuracy decay rate of Taoshi worm gear reducer is less than 0.5% after 2 million load tests, and the motion accuracy reaches ±0.015mm; the torque density reaches 500Nm/Kg; and the continuous working life is over 10,000 hours. It can stably realize 25kg level grip force. While maintaining the advantages of miniaturization (the weight of the whole machine is only 9-49g), it realizes 1-6Nm torque output of single joint.

In load test of dexterous hand joint module with 8mm center distance

Dynamic load capacity of 1.6kg for a 10cm arm (equivalent to fingertip end distance)

TaoShi Intelligent's ring surface envelope worm gear technology realizes the comprehensive improvement of transmission performance and reliability, providing a more competitive core transmission solution for robotic dexterous hands in pursuit of high load, high precision, and long-term reliable operation.

About Tao Shi

Tao Shi Intelligent Technology (Shenzhen) Co., Ltd. is a national high-tech enterprise, formerly known as "Shenzhen Tao Shi Precision Technology Co. The company is a Shenzhen Specialized Precision, Specialized New Enterprise, Central Government Supplier, AAA Credit Enterprise, Innovative Small and Medium-sized Enterprises. The company specializes in the research and development, production and sales of high-precision transmission components.

After 8 years of research and development, the original miniature ring surface envelope multi-tooth occlusion high-performance reducer is unique in the world's high-precision reducer field, and has won a number of national honors and a number of R & D patents. At present, Taoshi's miniature high-performance gearheads are widely used in a variety of high-tech fields such as high-precision industrial automation, industrial robotics, aerospace, military, medical equipment, humanoid robots and so on. With efficient and reliable transmission solutions, they provide strong support for various types of high-precision mechanical equipment.

Taoshi Intelligent Technology

Taoshi Intelligent Technology