Taoshi Gearboxes End Robot Joint Heat Dissipation Cycle with "Physical Split" Structure

On April 19th in Yizhuang, Beijing, a special marathon attracted global attention - 20 humanoid robotics teams competed in the first ever half-marathon. The "Tiangong" robot from the Beijing Humanoid Robotics Innovation Center took the lead in the race with a score of 2 hours and 40 minutes, winning the championship.

Racing exposes industry pain points:

Robots running and getting heatstroke?

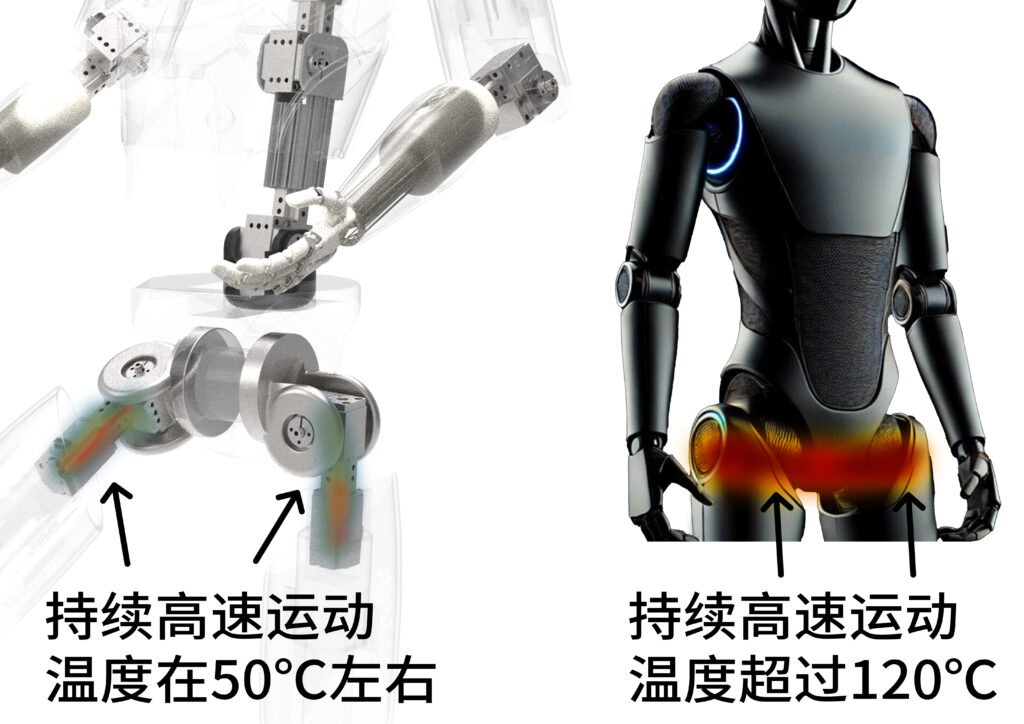

This science and technology marathon staged a number of "overturned" famous scene: some robots just started to fall, some robots lost their way, half of the robots ran to the middle of the sudden "strike", the staff had to hold up the cooling agent chasing the machine spray. Industry experts pointed out that the traditional robot joints as a "pressure cooker" - when the motor and reducer is integrated in the fist-sized space, high-speed operation of the double heat generated by the superposition of the temperature of the highest!Up to 120°C, this data exposes the inherent flaws of integrated joints - the superimposed effect of the motor and gearbox heat sources, which leads to a chain reaction of increased friction coefficients and uncontrolled thermal expansion of materials.

Tausch Joint Reducer Breaker:

Developed by Taoshi Intelligent TechnologyMicro annular envelope multi-tooth engagementreducer, three major thermal management innovations have been realized through the split structure design:

1. Dual heat source isolation architecture

Adopts a parallel mounting layout of motor and reducer to eliminate the heat transfer superposition effect. The architecture decouples the temperature rise curves of the two heat sources, significantly reducing core component temperatures.

2. Multi-tooth engagement black technology

Adoption of ring surface envelope worm gear multi-tooth meshing technology, single tooth contact stress from the traditional worm gear100% force reduced to 10%Even 5% force, the friction heat generation rate is reduced by at least 60%. Combined with the internal oil-cooling circulation system, the heat transfer path is effectively blocked.

3. Larger heat dissipation area

The motor can be mounted in a larger space such as the arm or calf, making it easier to dissipate heat.

Technological breakthroughs bring industrial revolution:

China's Intelligent Manufacturing Bends the Road to Overtake

Tao Shi as a domesticPioneer of miniature annular envelope worm gear technologyEnterprises, has built a complete high-precision transmission solutions. The technology not only solves the problem of robot joint overheating, but also promotes China's curved road in the field of precision reducer, its micro high-performance reducer has been in the aerospace, all kinds of robots and other fields to achieve import substitution. --Perhaps in the near future, we can see robots to complete a full marathon, and even compete with human athletes!

Taoshi Intelligent Technology

Taoshi Intelligent Technology