Dexterous hand joint technology route dispute: deciphering the Tao Shi ring surface envelope worm gear breakthrough code

In 2025, when the humanoid robot industry will explode, the dexterous hand joint, as the core component of the actuator, will directly determine the gripping accuracy, load capacity and service life of the design scheme. This article deeply analyzes the current mainstream technology route--sinewsdrive (transmission in an engine),Miniature Servo Cylinderstogether withTausch Ring Envelope Worm GearThe technological differences in gearboxes reveal how next-generation drive solutions are reshaping industry standards.

I. Advantages and disadvantages of key rope drive

comparative analysis

Strengths Analysis

1. Structural flexibility and lightweighting

- By mimicking the structure of human tendons, the tendon cords can move the actuator away from the actuating end, significantly reducing end loads and inertia.

- The light weight of a single tendon rope makes it suitable for scenarios where space is tight and multiple degrees of freedom are required for a dexterous hand.

2. Flexible transmission and shock resistance

- Tendon ropes can withstand bending and stretching, reducing the risk of mechanical damage by cushioning the impact force through elastic deformation in the event of a collision or accidental loading.

- When UHMWPE (Ultra High Molecular Weight Polyethylene Fiber) material is used, it can be up to 15 times stronger than steel, while maintaining its lightweight properties.

3. High adaptability of cabling

- Tendon cords can be routed along complex paths (e.g., through conduits or pulley blocks), supporting non-linear drives and adapting to the needs of dexterous hand bionic design.

disadvantageous analysis

1. Accuracy and lifetime limitations

- Motion accuracy is usually ±0.1mm, and after long-term use, it is easy to cause tension relaxation due to wear and tear, requiring frequent calibration.

- Typical loads have a short life span and require periodic replacement of the tendon rope, which is costly to maintain.

2. Environmental sensitivity

- Tendon ropes made of polymer materials are easy to deteriorate under high temperature or chemical corrosive environment; steel wire ropes, although temperature resistant, are easy to break due to repeated bending and are too heavy.

3. No self-locking properties

- Extra brake modules need to be installed and extra energy is consumed for long grips.

4. Slow response time

- Due to the delay of elastic deformation of the rope, the approximate response speed is 20-50ms, slower than the 10-15ms of the silk rod, and the response speed of the Taoshi speed reducer is <5ms (motor direct drive + rigid transmission).

5. Difficulty of reconciliation

- The tension and path of the rope needs to be precisely adjusted and may require complex adjustment mechanisms.

6. Grip slips easily

- Rope drive dexterity hand lack of rigidity, grip weights too much tension leads to letting force, easy to grip slip off.

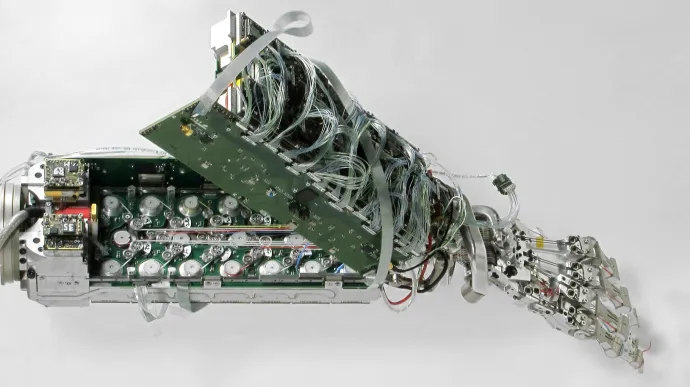

Second, micro servo electric cylinder advantages and disadvantages

comparative analysis

Strengths Analysis

1. High precision and high load capacity

- Rolling screws (e.g. planetary roller screws) have a positioning accuracy of ±0.03mm and can withstand axial loads of 10-100N class, making them suitable for precision gripping scenarios.

2. Long life and stability

- Ball or roller structure to reduce sliding friction, longer life, but daily screws need to pay attention to protection, pay attention to dust oil and other scenes, otherwise it is very easy to damage.

3. Partial self-locking and force control advantages

- Some screws (e.g. sliding screws) have a pseudo-self-locking feature, which maintains a certain amount of grip when the power is off, and loosens more slowly after the power is off, similar to a damping effect. If grip is required, the brakes need to be constantly powered.

disadvantageous analysis

1. Volume and weight constraints

- Miniature screw module weights are generally in the range of 20-35g, an increase of about 30% over the tendon rope solution (15-30g), limiting high-density joint layouts.

- Complex drive structures take up a lot of space and require sacrificing some of the number of degrees of freedom.

2. Cost and maintenance thresholds

- Planetary Roller Screws have a high unit cost and require nanometer-level machining accuracy.

-Installation requires strict coaxial alignment and is more difficult to maintain than tendon rope systems.

3. Weak impact resistance

-Rigid transmission structures are prone to stalling or deformation under sudden loads and require additional design of cushioning mechanisms.

4. Restricted environment of use

-Because of the special characteristics of the screw, there are high requirements for the use of the environment, otherwise, due to dust particles and other particles into the joints, will greatly shorten the service life, or even on-the-spot damage.

5. Lack of freedom

- Because the planetary roller screws plus motor size is large, so generally deployed in the palm of the hand inside, generally 6 degrees of freedom or 10 degrees of freedom, and the palm of the hand is also deployed in the circuit boards and so on, resulting in the palm of the hand is particularly thick.

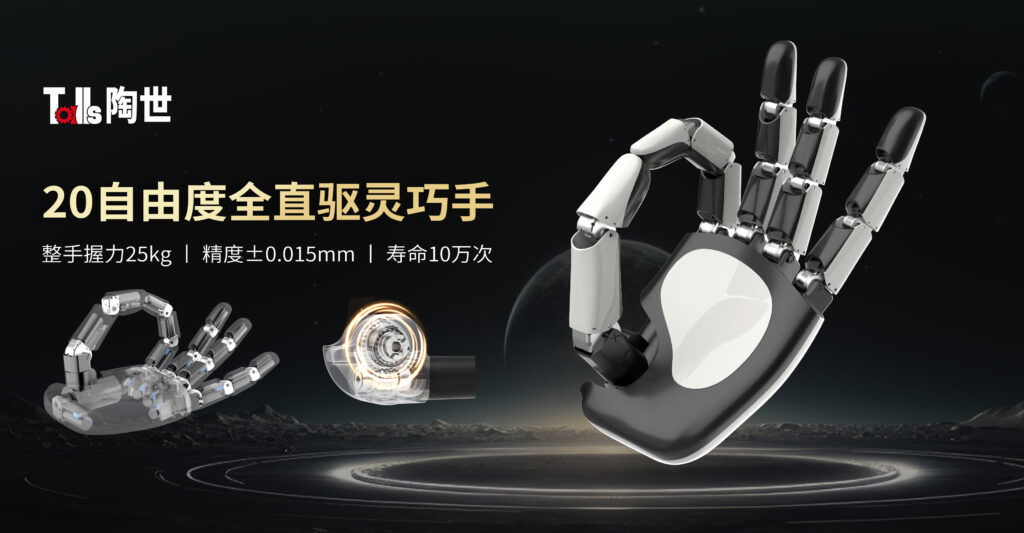

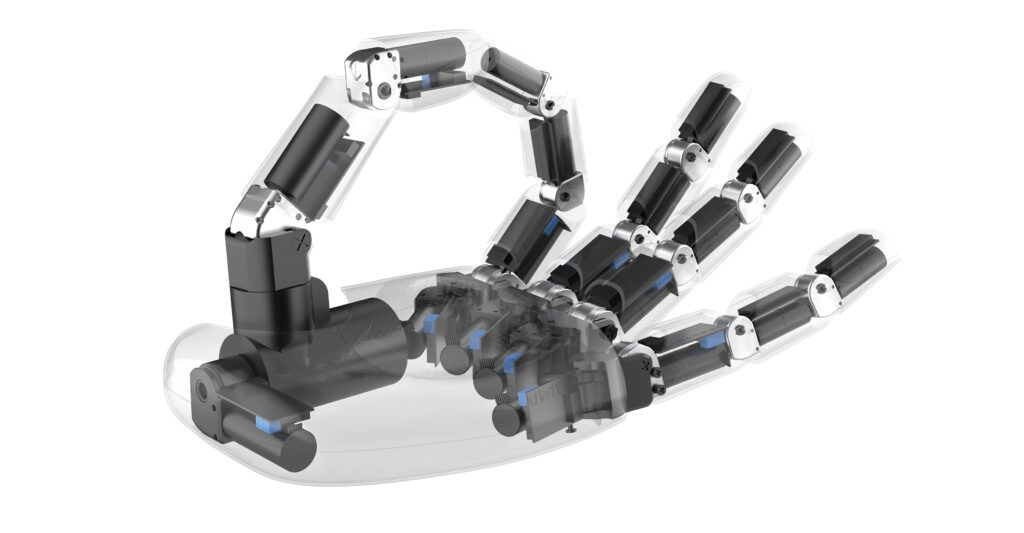

III. Advantages and disadvantages of Taoshi ring surface enveloping worm gear transmission

comparative analysis

Strengths Analysis

1. High precision and high load capacity

- The Taoshi ring-face enveloped worm gear reducer has a positioning accuracy of ±0.015mm and can withstand axial loads of 56-300N class, making it suitable for precision gripping scenarios.

- Peak torque up to 6 NM and rated torque up to 3 NM for single joints.

2. Failure to transmit rigidity and accuracy errors

- Circumferential envelope reducer, direct drive transmission, no transfer of rigidity error, no transfer of accuracy error.

3. Minimal space requirements

- Integrated joint module, small size, high torque, the same torque, the volume reduction of at least 30%.

- The single-joint reducer weighs only 9-49 g. Natural 90° drive without additional steering.

4. Long service life

- Long operating life of 10,000 hours or more. More than 100,000 times of load operation.

- IP65 rated protection for use in complex environments and for extreme climates.

5. Advantages of self-locking and force control

- The 100%'s self-locking performance allows you to grip things for a long time after they have been gripped without the need for additional power.

6. Good thermal performance

- The temperature is always kept at about 50℃ for long time operation, which ensures the stable operation of the motor and reducer.

7. Integrated performance leadership

- The Taoshi ring surface envelope multi-tooth mesh design allows the reducer noise to be as low as 50 dB or less.

- With a tensile strength of up to 1300 MPa, the impact resistance is at least 3 times higher than that of a screw.

8. Lower costs

- The structure of Taoshi reducer is simple. Judging from the physical level, the gear set is less in number, simpler in structure and easier to assemble compared to the devices such as screws and harmonics. So the cost is lower after mass production.

Ring Envelope Worm Gear vs. Ordinary Worm Gear

disadvantageous analysis

1. Lower transmission efficiency

- The Taoshi ring surface envelope multi-tooth meshing structure is at least 100% more efficient than the traditional worm gear structure, up to 60%-90%, which is comparable to the key rope. However, the actual comprehensive energy consumption is lower due to the self-locking function.

2. Insufficient flexibility

- Due to the purely rigid structure, it is not as flexible as a key rope, and is more suitable for industrial scenarios, or high sensitivity scenarios.

concluding remarks

Keystrokes:If high flexibility is required (e.g., scientific research, education, home scenarios, etc.), and torque and accuracy are not required for theKey rope methodis the more appropriate choice.

Miniature servo electric cylinder:If high precision and force control capabilities are required (e.g., service robots, precision assembly scenarios, etc.), theMiniature Servo Cylindersis the more appropriate choice.

High precision worm gear structure:If high loads with self-locking characteristics are required (e.g. industrial robots, heavy gripping, etc.).High Precision Worm Gear StructureMore appropriate.

Taoshi Intelligent Technology

Taoshi Intelligent Technology