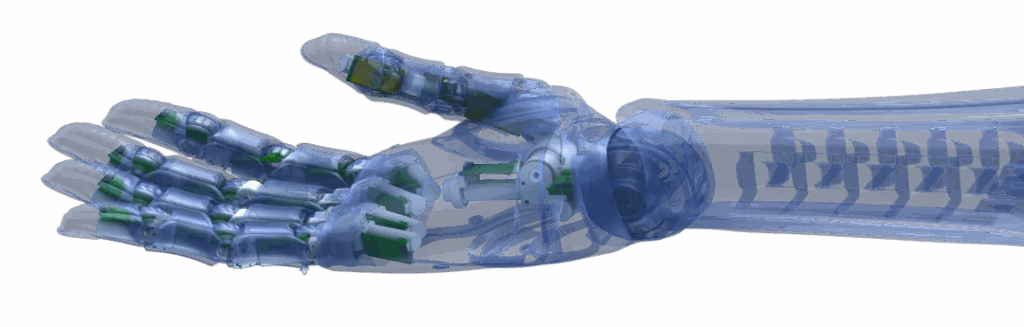

A fully closed-loop, fully direct-drive dexterous hand drive technology has been introduced.

01

Background and development of the dexterity industry

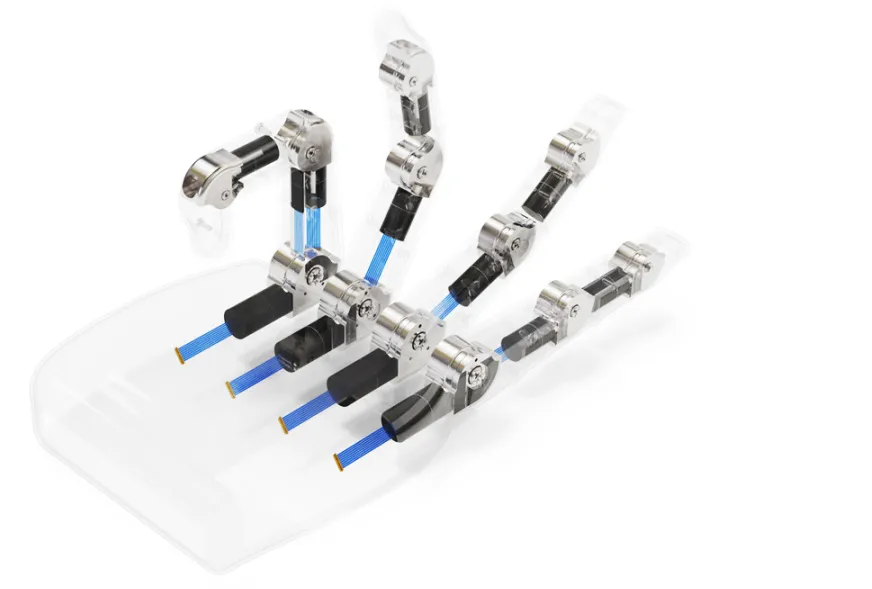

With the rapid development of roboticsdexterous handsAs the core component of robot end-effector, its performance directly determines the robot's performance and scope of application in complex tasks. The global dexterous hand industry presentsa hundred flowers bloom, a hundred schools of thought contend (idiom); refers the classical philosophic schools of thoughtsituation, companies continue to exploreDifferent technological routesto achieve higher degrees of freedom, more precise control, and a wider range of application scenarios.

The current industry definition of dexterous hand freedom existsBigger MisconceptionsSome dexterous hands advertise having 20+ joints as having 20+ degrees of freedom, but they don't have a separate set of motor drives for each of those 20+ joints, they may only have 6 motor drives, which is actually6 degrees of freedom, not 20+.. True degrees of freedom should mean that each joint is equipped with an independent drive motor, and the number of degrees of freedom should be equal to the number of drive motors, not simply measured by the number of joints.

02

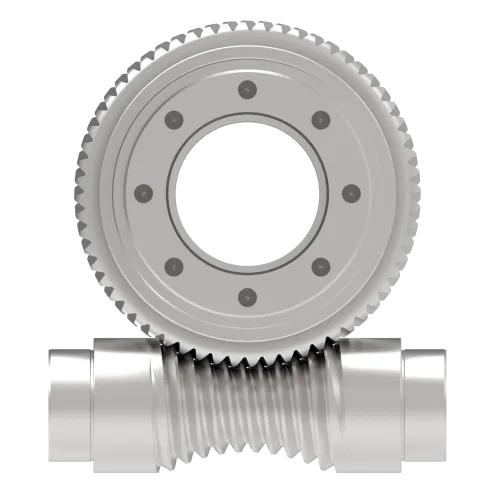

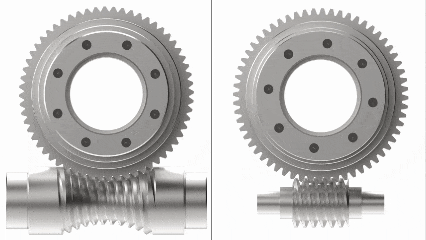

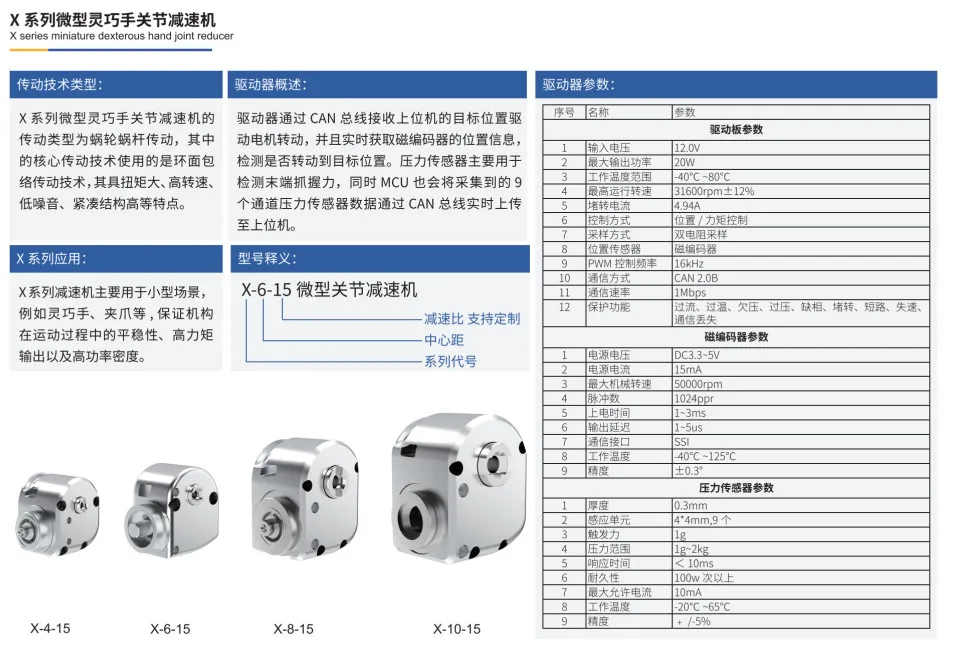

Circumferential Envelope Worm Gear Direct Drive Technology

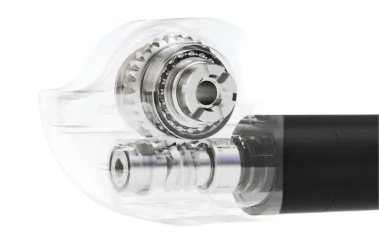

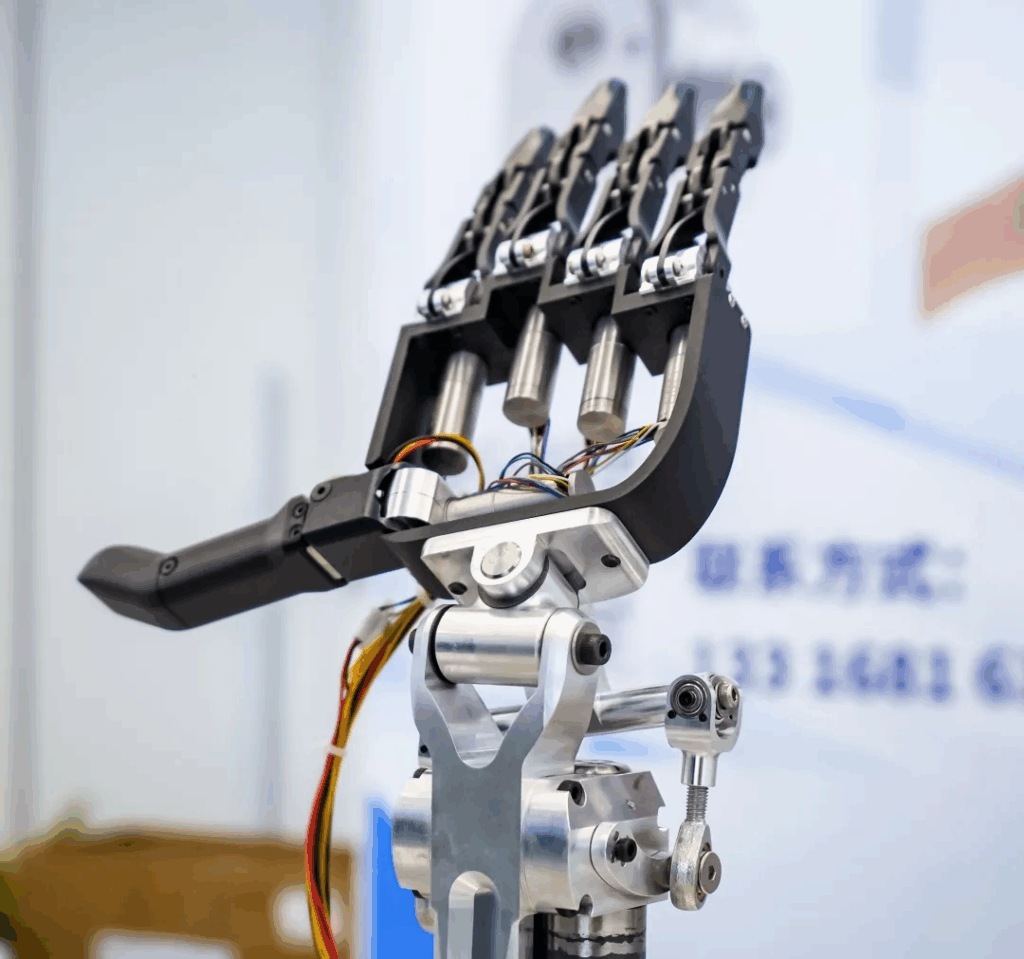

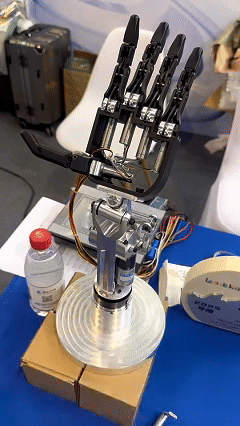

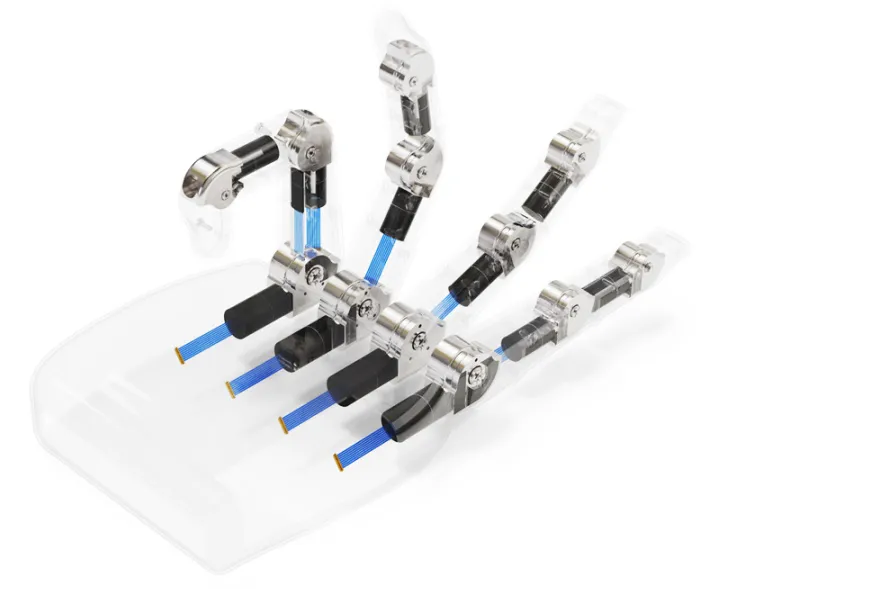

As technology evolves, a new type of driveCircumferential Envelope Worm Gear Direct Drive TechnologyStanding out from the rest, it adopts the principle of ring surface envelope multi-tooth meshing, and each reducer is highly integrated with drivers, brushless motors, and encoders, which truly realize the20+ Direct Drive Degrees of FreedomThe

Ring Envelope Worm Gear vs. Ordinary Worm Gear

with respect toRing Envelope Worm Gear Technology DevelopmentThe presentation can be accessed by providing this link:

https://mp.weixin.qq.com/s/35P5Z-fVmfAu1aCiVj_ZaQ

03

Technical characteristics

More rigidity and stability:Direct-drive construction reduces intermediate transmission links, reducing wear and tear and failure rates.

Full closed-loop control:Real-time feedback and precise control, fast response and high precision.

High precision transmission:The ring-enveloped worm gear transmission allows for extremely high transmission accuracy and ensures the accuracy of the gripping action.

Highly integrated:Each joint module is highly integrated, compact and easy to maintain.

04

Technical Advantages

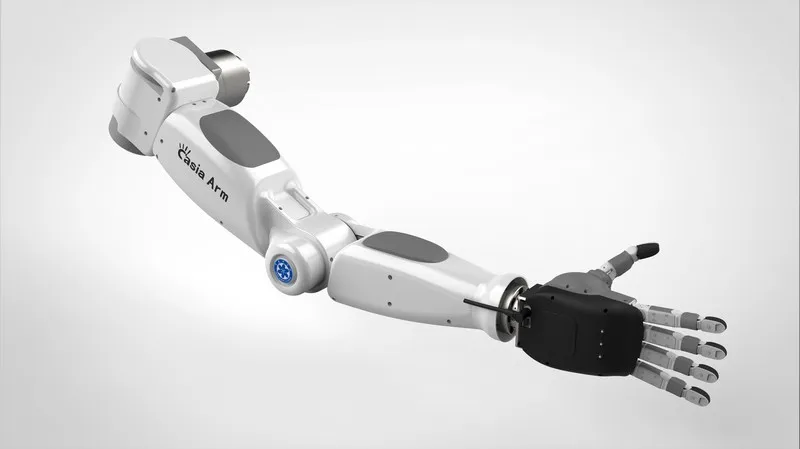

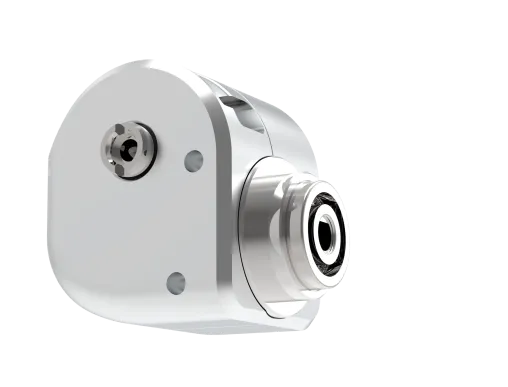

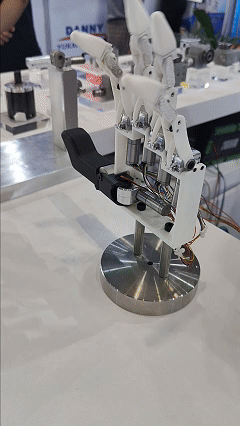

inimitable90 degree outputThe drive motor can be embedded inside the finger, well adapted to the physical structure of the finger, very small size, very light weight, compared with planetary ball screw drive, ring surface envelope drive technology in the flexibility and degree of freedom to achieve a breakthrough in the improvement. Compared to wire rope drive, ring surface envelope drive technology is significantly better in terms of control accuracy, grip control stability and reliability.Outstanding overall performance, more suitable for complex, high-precision tasksThe

05

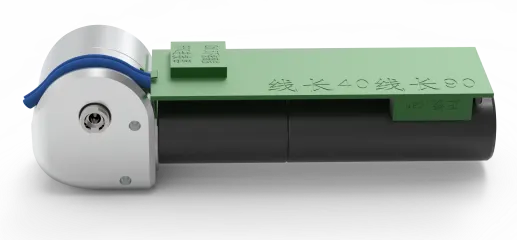

Miniaturized high-torque design

Miniaturized high-torque design, based on a miniature ring-enveloped worm gear structure, reducer module size compared to traditional solutionsShrink 40%Center distance coverage4.5mm-10mm full sizeScope. Match1300MPa tensile strengthSpecial steel internal teeth for stable25kg class grip.. While maintaining the advantages of miniaturization (wholeWeight only 9-49g) while realizing single-joint1-3N m torqueoutput, the torque density reaches 2.3 times that of similar products in the industry. Its 9g ultra-lightweight design (equivalent to the weight of 3 coins), for dexterous hand joint moduleSave 30% spaceThe end-effector of the humanoid robot has a significantly higher degree of anthropomorphization. All-conditions reliability guarantee Integrated natural self-locking function andIP65 protectiongrade, maintaining joint posture stabilization even in the event of a power failure, by2 million loadsTested accuracy attenuation rate is less than 0.5% and is suitable for extreme environments from -40℃ to 85℃.

06

Breaking the boundaries of dexterity transmission

Tao Shi's original micro-ring surface envelope drive technology is a disruptive innovation that pushes the boundaries of dexterous hand drive because he can mount the reducer inside the fingerdirect driveFinger joints, which is currently the world's only leading technology to drive finger joints with reducers, a dexterous hand can be deployed inside more than 20 such reducers, the dexterous hand to realize the20+ degrees of freedomFull direct drive control, per articulated modulestand-alone operationboth (... and...)Extremely high torque and precision. It can easily realize all kinds of complex movements with its±0.015mm motion accuracy, far exceeding the industry average level of 0.05mm.

Taoshi Intelligent Technology

Taoshi Intelligent Technology