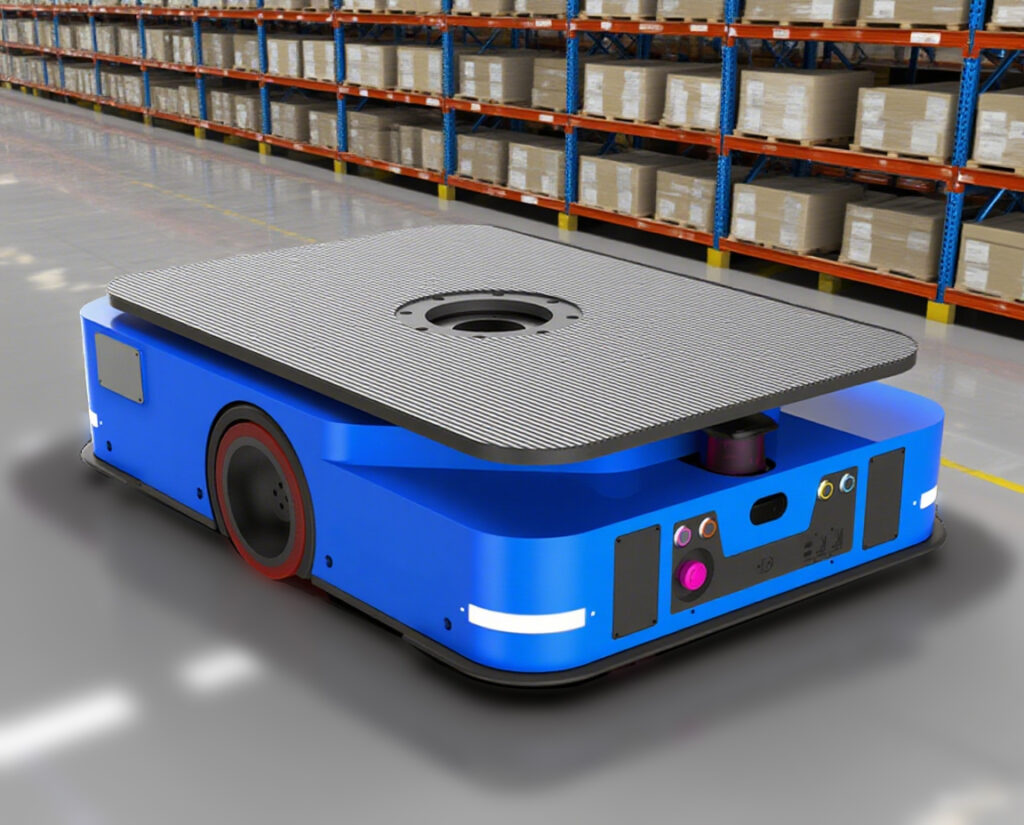

Advantages and technical analysis of the application of Taoshi reducers in the AGV industry

01

High precision and dynamic stability

Core Assurance for AGV Navigation

The Taosi gearboxes are made ofCircumferential Envelope Worm Gear StructureThe following are some examples of the types of loads that can be realized under dynamic loading conditionsHigh precision output of ±1 arc minuteThis feature is essential for AGV path tracking and positioning. This feature is essential for AGV path tracking and localization:

Precision Navigation:AGVs need to achieve ±5mm level positioning between narrow shelves (such as laser SLAM navigation requirements), traditional planetary gearboxes are prone to path shifting due to gear backlash, while the multi-tooth mesh design of Taoshi's gearboxes enhances the contact area to 3 times that of the traditional structure, effectively dispersing the inter-tooth stress, and providing a precision attenuation rate after long-term use of < 0.5%.

Impact resistance:In storage scenarios, AGVs often need to make emergency stops or avoid obstacles. The Taoshi reducer can reach 1300MPa tensile strength, and its material belongs to the category of ultra-high-strength materials, which are widely used in automotive safety components, aerospace structures and key mechanical connectors. It allows AGVs to avoid transmission failures caused by vibration.

02

self-locking function

Double breakthrough in safety and energy efficiency

The natural self-locking characteristics of Taos gearboxes show significant advantages in AGV ramp operations:

Passive safety protection:While traditional AGVs need to be additionally equipped with electromagnetic braking system (cost increase of about 15%), Taoshi gearboxes automatically lock in case of power failure or load failure to prevent the risk of slippage. For example, when the unmanned forklift lifts 1200mm height, the self-locking function ensures static stability under large loads. During the uphill process, in case of insufficient power or power failure, it can stop steadily on the ramp without slipping back, ensuring the safety of personnel, goods and site.

Energy consumption optimization:The self-locking function reduces the energy consumption of the holding brake, and the measurement shows that it can reduce the overall power consumption of the AGV 12%-18% and extend the AGV battery life.

03

Compact design and space utilization innovation

The 90° right-angle drive and miniaturized construction of the Taos gearboxes revolutionize AGV design:

Volume reduction 30%:Compared to the same torque RV/harmonic reducer, the Taoshi reducer has a volume reduction of approximately 30%, which allows for better repositioning or layout of other configurations in limited spaces.

Flexible layout:The lateral motor mounting design frees up space at the bottom of the AGV for the integration of LIDAR or vision sensors. For example, an e-commerce warehouse AGV shortens the distance between the navigation module and the drive system by 40% through this design, which improves the accuracy of map building.

Shorter height:The Taoshi reducer uses 90 degrees of orthogonal involvement, which is more suitable for low-profile use, and isthe only one of its kind in the worldRealization of low profile intelligent forkliftsHeight 9 cmRequirements. Reduces vertical footprint by 251 TP3T compared to the current market-optimized 12cm solution, while maintaining strong load and shock resistance.

04

Silence and durability

Adaptable to high-intensity operating environments

Ultra-low noise (<50 dB):Through tooth shape optimization and material optimization, Taoshi reduces the noise at high speeds by 60% compared to traditional harmonic reducers, making the final noise under 50 dB, making the application environment very quiet.

2 million life tests:In the actual application environment, after 10,000 hours of continuous operation, the wear of AGVs equipped with Taoshi gearboxes is only 1/5 of that of traditional worm gears, and the maintenance cycle is extended to 2 years.

05

Industry application cases and user testimonials

E-commerce warehousing AGVs:Submerged AGVs using Taoshi gearboxes achieve 99.81 TP3T of trouble-free operation in normal environments, reducing downtime by 701 TP3T compared to the original gearbox solution.

Unmanned Forklift Project:An AGV factory adopts Taoshi gearboxes to drive unmanned forklift trucks with a load of 600kg, and the daily mileage of a single machine has been increased to 45km (industry average 30km), and the temperature rise of the motor has always been kept at about 50℃ without heating problems.

06

Comparison of technical parameters

Crushing traditional programs

| norm | Taoshi Speed Reducer | Planetary reducer | Harmonic reducer |

| efficiencies | 70%-90% | 85%-97% | 70%-90% |

| static (in a signal)(dB) | <50 | 65-75 | 55-65 |

| self-locking function | there are | not have | not have |

| torque density(Nm/kg) | 500 | 200 | 300 |

| longevity(hours) | 20000 | 10000 | 6000 |

| accurate(arcseconds) | 60 | 360 | 60 |

07

Industry trends and market fit

With the AGV market growing at a compound annual growth rate of 25% (the scale will exceed 40 billion yuan in 2026), the technical advantages of Taoshi gearboxes are highly matched to the industry's needs:

Cost advantage:The cost after mass production is 30% lower than that of harmonic reducer, which helps AGV manufacturers to maintain gross profit in the price war.

Domestic substitution:In the "14th Five-Year Plan" intelligent manufacturing policy to promote, Tao Shi reducer has been gradually replaced by Japan Sumitomo, Harmonaco and other imported brands of reducer program, the domestic market share increased annually.

Taoshi reducer throughHigh precision transmission, self-locking, miniaturized designThree core technologies that are reshaping the AGV drive standard. With logistics automation and smart manufacturing upgrades, its "small but mighty"The characteristics will become a key choice for AGV manufacturers to enhance their competitiveness.

Taoshi Intelligent Technology

Taoshi Intelligent Technology