Enabling the new future of intelligent manufacturing 丨Taoshi Intelligence will be present at the 2025 China Body Intelligent Robotics Industry Conference

Enabling the new future of intelligent manufacturing 丨Taoshi Intelligence will be present at the 2025 China Body Intelligent Robotics Industry Conference

2025 China Embodied Intelligent Robotics Industry Conference

The "2025 China Embodied Intelligent Robotics Industry Conference & Exhibition" will be held on August 13-15, 2025 at Shanghai New International Expo Center, jointly organized by Inverconferences & Exhibitions (Shanghai) Ltd. and the Chinese Society of Electrotechnology, the Thousands of Electric Vehicles Association and other related organizations. The conference will continue to build a one-stop value docking platform integrating "conference + exhibition + event", and is expected to attract 200+ exhibiting brands, 20,000+ visitors and 20+ professional purchasing groups, helping to open up the body-intelligent industry chain from raw materials, parts suppliers, system integrators, simulation and testing to machine manufacturing, providing the industry with a comprehensive showcase of cutting-edge technologies, components, systems integrators, simulation and testing to machine manufacturing. It will provide a stage for the industry to comprehensively display cutting-edge technologies and programs, deeply communicate with the industry and promote resource docking.

Technical Highlights:Revolutionary upgrade of direct-drive articulating modules

The core innovation of the Taos dexterous hand solution is its fully direct-drive articulating module, with specific benefits including:

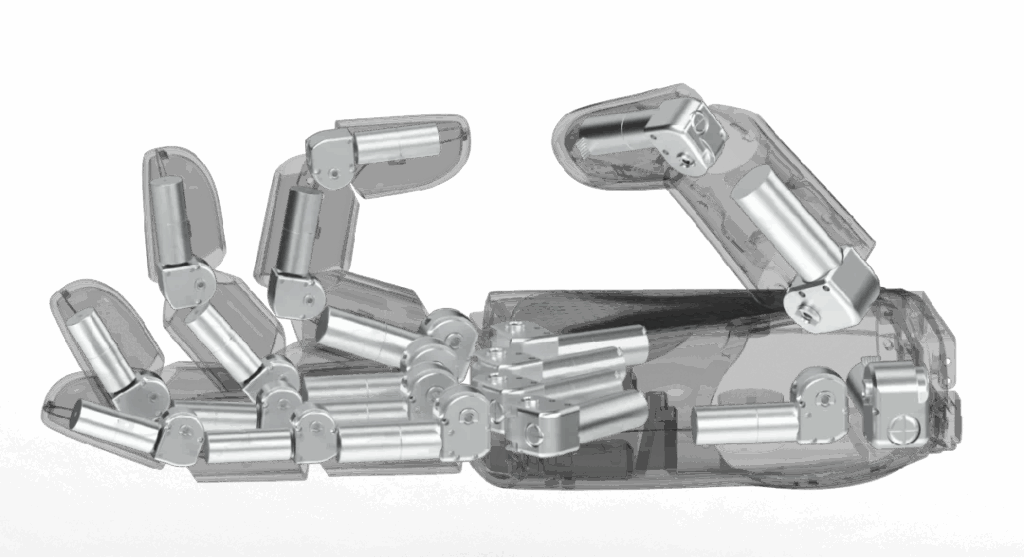

Dexterous hand joint module

Extreme miniaturization and high degree of freedom

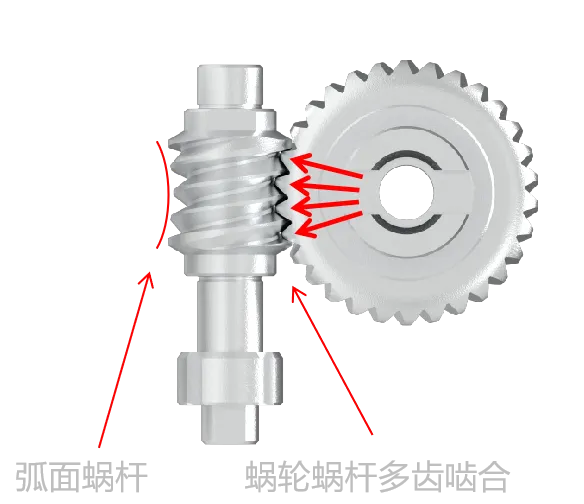

▶ Whole Hand Integration20 direct drive degrees of freedomThe volume of the joint module is comparable to that of a manual joint, and the volume of the gearbox is reduced by the ring-enveloped worm gear structure.Shrink 40%For Robot FingersSave 30%Space.

▶ Single-joint torque up to6NmThe torque density is 2.3 times that of similar products in the industry, making it easy to lift at your fingertips.1.6kgWeights.

Precision control and long life

▶ Output accuracy up to±1.5 arcminAdaptationPrecision assemblyand other scenes.

▶ Special steel material and self-lubricating coating are used, and the measured life is more than10,000 hoursSupport-40°C to 85°CExtreme environments.

Energy efficiency and stability breakthroughs

▶Natural self-locking design:Automatic locking of the joint posture in case of power failure, without additional braking system.Reduced energy consumption 30%The

▶ Heat dissipation is stable:Highly efficient heat dissipation design, continuous working temperature stabilized atAround 30°CThe

Industry Significance:Revolutionary upgrade of direct-drive articulating modules

Directly hit the pain points of the industry

Solving the bottleneck of traditional speed reducer

▶ Circumferential envelope structure increases the contact area through the full envelope design of the tooth surface, significantly reduces wear and improves accuracy, while improving transmission efficiency, overcoming the defects of low efficiency and easy to wear of the traditional worm gear transmission.

Enabling highly dynamic scenes

▶ High torque density and miniaturization characteristics enable humanoid robots to perform complex tasks such as precision tool manipulation and irregular object grasping, accelerating the penetration of applications in medical and industrial fields.

Smaller size, higher torque

▶ Making dexterous hands more anthropomorphic, high torque can give robots greater possibilities.

Exhibitions

📍 Booth #: 2B088 in Hall N2

📍 Time: August 13-15, 2025

📍 Location: Shanghai New International Expo Center

Taoshi Intelligent Technology

Taoshi Intelligent Technology