Demystifying Innovative Solutions for Robot Joints: Drive Technology Innovations with Tausch Ring Surface Envelope Reducers

I. Overview of technological innovations

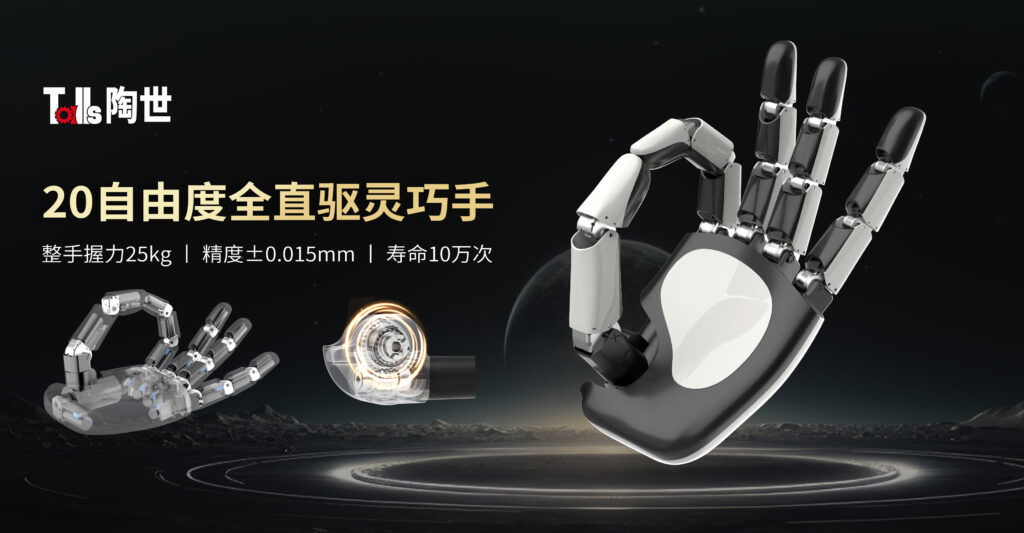

Taoiseach Intelligent Technology presentsRing surface envelope reducerWith itsMiniaturization, high torque, ultra-precisionand other features are reshaping the technological boundaries of robotic joint drives. As the world's first high-torque speed reducer that can be deployed at the tip of a dexterous fingertip, it utilizes an annular envelope worm gear structure, and is available in20+ degrees of freedomFull direct drive control,±0.015mmMotion accuracy, single joint20kg loadWhole handGrip strength 25kgand other indicators to achieve breakthroughs. This technology not only solves the contradiction between the volume and torque of traditional speed reducers, but also shows disruptive potential in highly sensitive scenarios such as medical surgery and precision assembly.

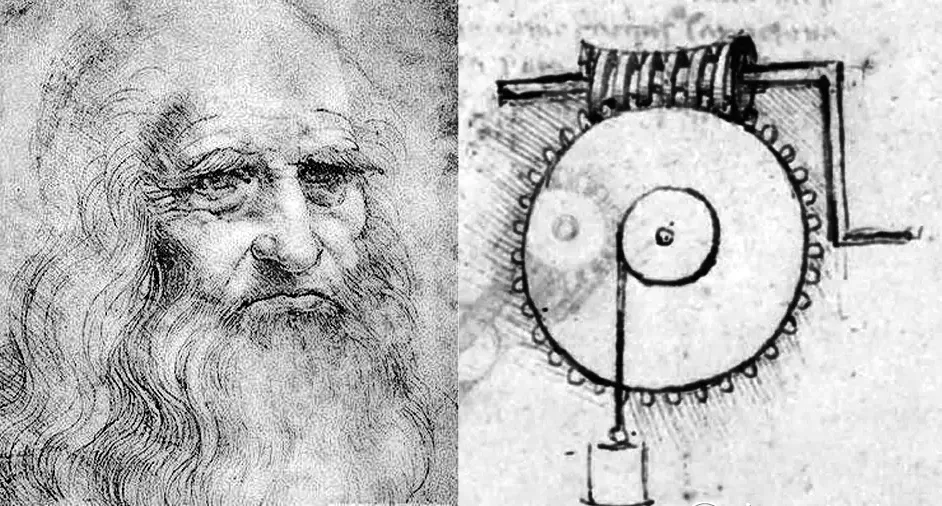

II. Historical traceability: from da Vinci's manuscripts to modern industry

The mechanical design idea of ring surface envelope can be traced back to the Renaissance. The worm gears depicted in Leonardo da Vinci's manuscripts do not directly present the concept of "ring surface envelope", but they are useful for the design ofmultitooth gearingThe exploration with the curved surface drive has shown its beginnings. Because the structure is special, subject to the industrial production technology in those years, has not been realized. Until the modern industry, this theory was standardized in the 1990s as a planar secondary envelope ring face worm gear transmission, which forms a high-precision tooth contact through the envelope machining of the plane mother face and the relative motion. Based on this, Tao Shi's team combined miniaturized manufacturing processes to design theExclusive tooth shape, taking this classic structure to new heights.

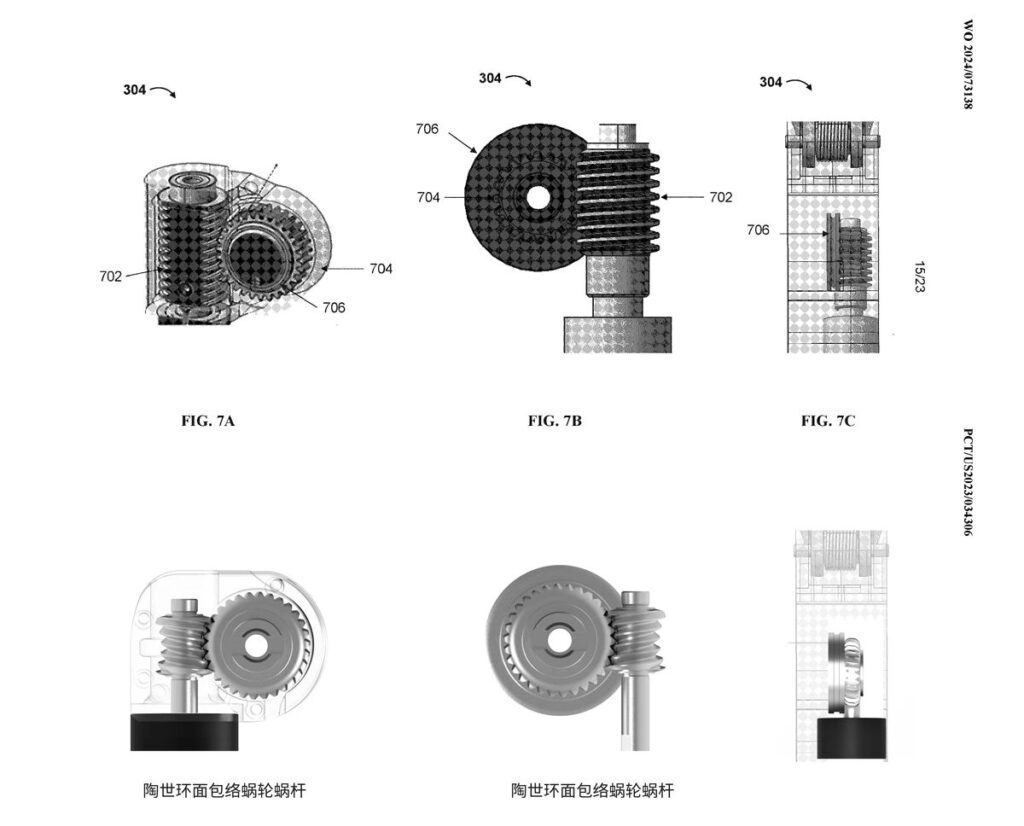

Structure analysis: the ultimate balance of miniaturization and high torque

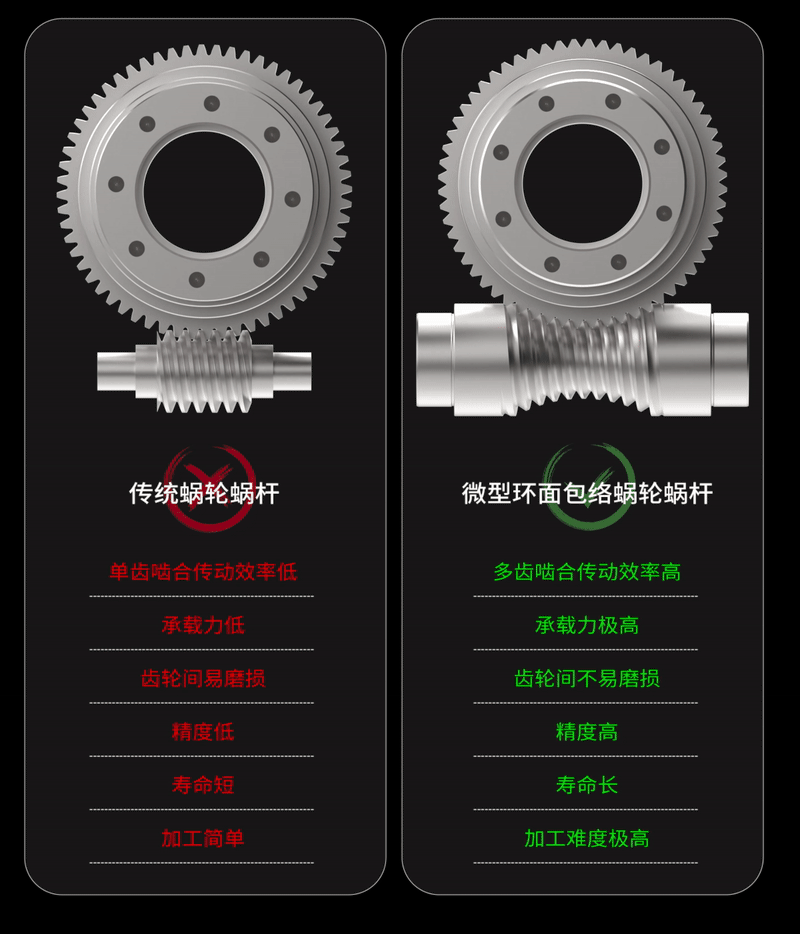

The core structure of the ring surface envelope reducer contains two major innovations:

Multi-tooth engagement design:The tooth surface of the worm gear is designed through an exclusive structure.Effective contact area up to 85%The number of teeth that can be enveloped can reach30% of the total number of teeth. The contact area is increased to that of a conventional structure3 times moreThe torque density can be as high as500Nm/kg, far exceeding similar products.

Miniaturized integrated technology:Adoption of 4.5-10mm center distance ring surface enveloped worm gear, the volume is more than the traditional solution.Shrink 40%The weight is only 9-49g, yet it enables1-3N-mThe powerful torque output of the

Fourth, the performance advantage: redefine the miniature reducer

Multiple breakthroughs in Taosi ring surface envelope reducers:

Ultra-high precision:Absolute positioning accuracy±0.5 arcminRepeatable positioning error≤0.015mmthat meets the robot's need for micrometer-level control of movements.

Silence and Reliability:Optimized by exclusive gear shape design, the operating noise is reduced to50 dB or less(library environment equivalent), IP65 protection ratingSupports -40°C to 85°CExtreme working conditions.

Energy consumption optimization:Natural self-lockingFunction reduces the energy consumption of the holding brake and allows it to remain stationary without the need for an additional braking system, for a continuous working life.Over 10,000 hoursThe

Cost Controllability:structural designsimplerThe assembly complexity is alsoless, mass production cost compared to harmonic, RV solutionslessThe

more efficient::Its efficiency is up to70-90%The 40% is twice as efficient as a conventional worm gear.

More efficient heat dissipation:The physical separation design of its transmission unit and drive motor completely solves the problem of heat coupling of traditional integrated joints. The long time running temperature is always kept atAround 30°TheNo cooling system is required.

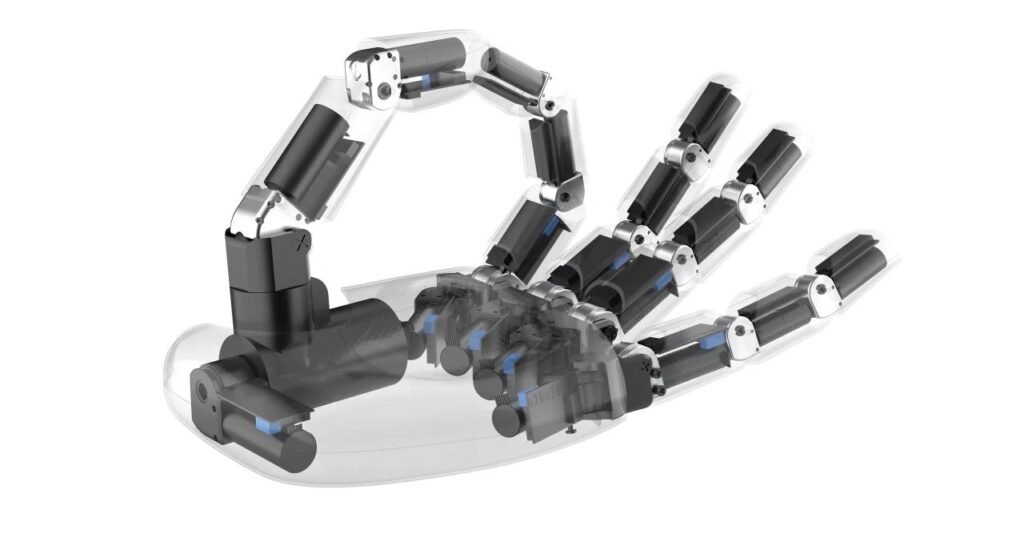

V. Dexterous hand applications: the ultimate form of robotic manipulation

In the dexterous hand scenario, the value of the ring surface envelope reducer was able tofull release::

Freedom Breaks:Single finger with 4 integrated articulation modules, supports20+ degrees of freedomFull direct-drive control for easier training, more flexible operation, and compact size.

Load capacity jumps:static (as in electrostatic force)The load capacity is 20kg at the single joint and 5kg at the fingertip end. in thedynamic (science)Carrying a static load of 4kg in the lower joint and 1.6kg at the end of the fingertip. far exceeding the industry average.

Flexible adaptation:The modular design supports quick changeover and is suitable for multiple scenarios such as industrial assembly, medical surgery and home service.

VI. Disruptive substitution: optimizing paths for Tesla's dexterous hand solution

Compared to Tesla's existing worm gear underdrive solution, Taosi's ring surface envelope technology provides a triple upgrade:

spatial compression

‣ Replacement reduces the thickness of a single finger by 35%, freeing up space in the palm and allowing the integration of more sensors.

Torque Reinforcement

‣ Output torque increase of 200% for the same volume (Tesla's current program fingertip torque ≤ 1N-m), and grip strength jumps from 5kg class to 25kg.

Reliability multiplier

‣ Multi-tooth mesh design spreads contact stresses across multiple tooth surfaces (conventional construction is single-tooth only), resulting in a breakthrough in life from 3,000 hours to 10,000 hours +.

Defining the Next Generation Joint Paradigm

Tausch ring surface envelope reducer throughSeparate Heat Dissipation,Full direct drive control,Bionic MiniaturizationTrinity innovation solves the "heat-force-control" triangle paradox of high-density joints. Its potential to replace Tesla and other head solutions marks the evolution of robotic joints from "function realization" to "performance maximization". As humanoid robots enter human work and life scenarios, this technology will become the cornerstone of reliability.

Taoshi Intelligent Technology

Taoshi Intelligent Technology