Ring Envelope Reducer vs. Corner Reducer: A Technological Innovation in Precision Drives

In the field of industrial automation and robotics, the corner reducer has long played an indispensable role. This device, which can realize 90-degree power transmission, effectively solves the problem of spatial layout of equipment by changing the transmission direction, and has become an indispensable key component in automated production lines, robotic arms, and logistics and conveying systems.

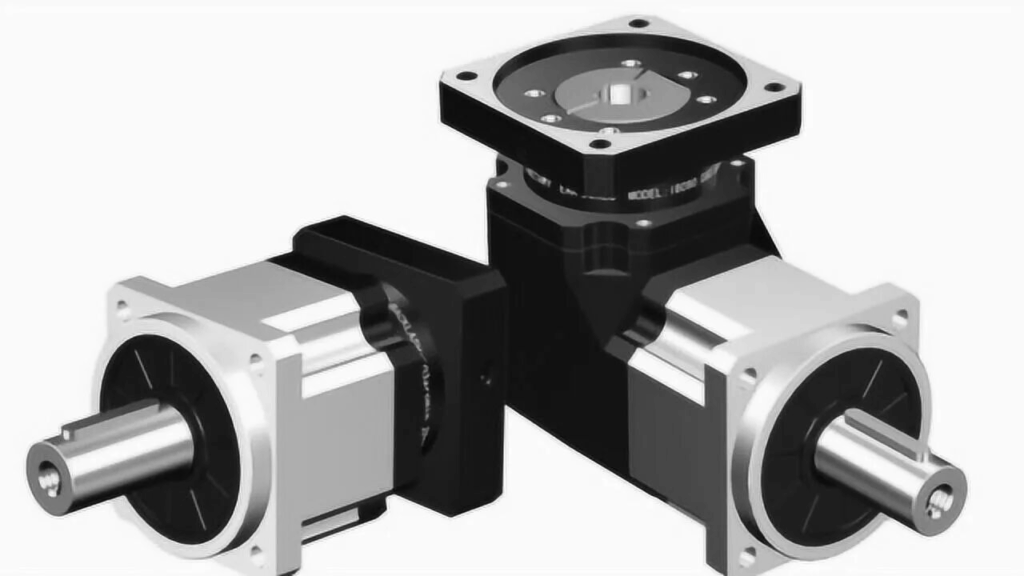

In traditional industrial design, corner reducers have won the trust of engineers for their reliability and versatility. The mainstream corner reducers on the market fall into two main categories:

One category is the high-efficiency transmission type based on planetary gear structure;

Another type is the self-locking type based on worm gears.

The former has high transmission efficiency but lacks self-locking function, while the latter has self-locking capability but low transmission efficiency.

With the rapid development of industrial technology in the direction of precision, miniaturization and high efficiency, the limitations of the traditional corner reducer have become increasingly prominent, and have become a bottleneck that restricts the improvement of equipment performance.

- expensiveIs the primary problem faced. High-quality corner reducers can easily cost thousands of dollars or even tens of thousands of dollars for a single unit. For complex equipment that requires multiple speed reducers, this part of the cost occupies a considerable proportion. In order to realize the complete transmission system, often also need to purchase additional brakes and other supporting components, further pushing up the overall cost.

- bulkyIs another defect that is difficult to avoid. Due to the limitations of structural design, the traditional corner reducer needs to occupy a large installation space when realizing right-angle transmission. This drawback is especially prominent in applications where space is extremely limited, such as robotic dexterous hands and precision medical equipment.

- inefficiencyThe problem of the same should not be ignored. In particular, the use of worm gear structure of the corner reducer, its transmission efficiency is usually only about 40%, meaning that most of the input energy in the transmission process in the form of heat dissipation for nothing. The waste of energy also causes the system to heat up, requiring additional cooling measures, further increasing the complexity and cost of the system.

- Insufficient precisionIt also limits the performance improvement of the equipment. The traditional corner reducer is difficult to meet the demanding requirements for precise positioning in high-end manufacturing due to the large backlash and limited transmission accuracy. In applications requiring micron-level control, this shortcoming has become a major obstacle to technological breakthroughs.

Revolutionary Solution: Taos Ring Surface Envelope Reducers

Faced with the pain points of traditional corner reducers, the Taoshi ring face envelope brings an innovative solution.

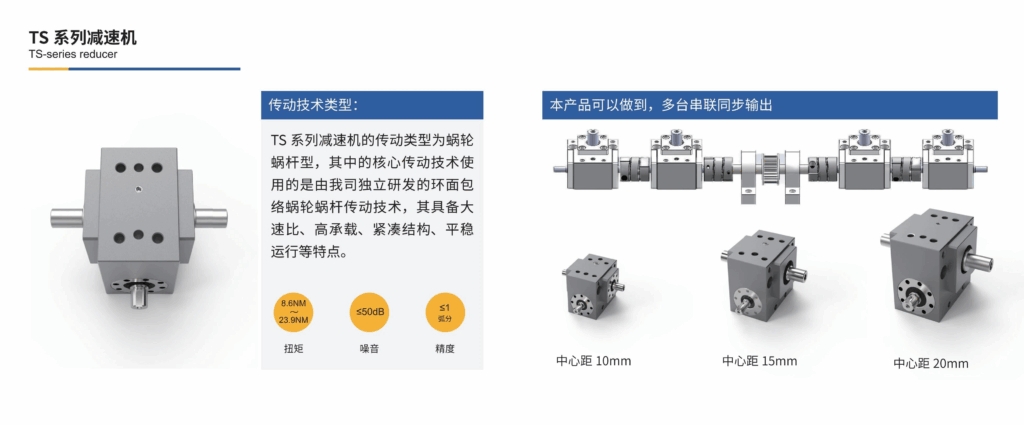

This innovative product based on ring surface envelope worm gear technology fundamentally solves the inherent defects of traditional corner reducers. Its unique multi-tooth meshing design enables the effective contact area to reach 85%, while the percentage of teeth involved in meshing is as high as 30%, which not only greatly improves the transmission efficiency, but also significantly enhances the load carrying capacity.

Multi-tooth meshing vs. single-tooth meshing

on the basis ofRing Envelope Worm Gear TechnologyIt is an innovative product that fundamentally solves the inherent defects of traditional corner reducers. Its unique multi-tooth mesh design, so that the effective contact area of 85%, while the number of teeth involved in the mesh accounted for as high as 30%, not only significantly improve the transmission efficiency, but also significantly enhance the load-bearing capacity.

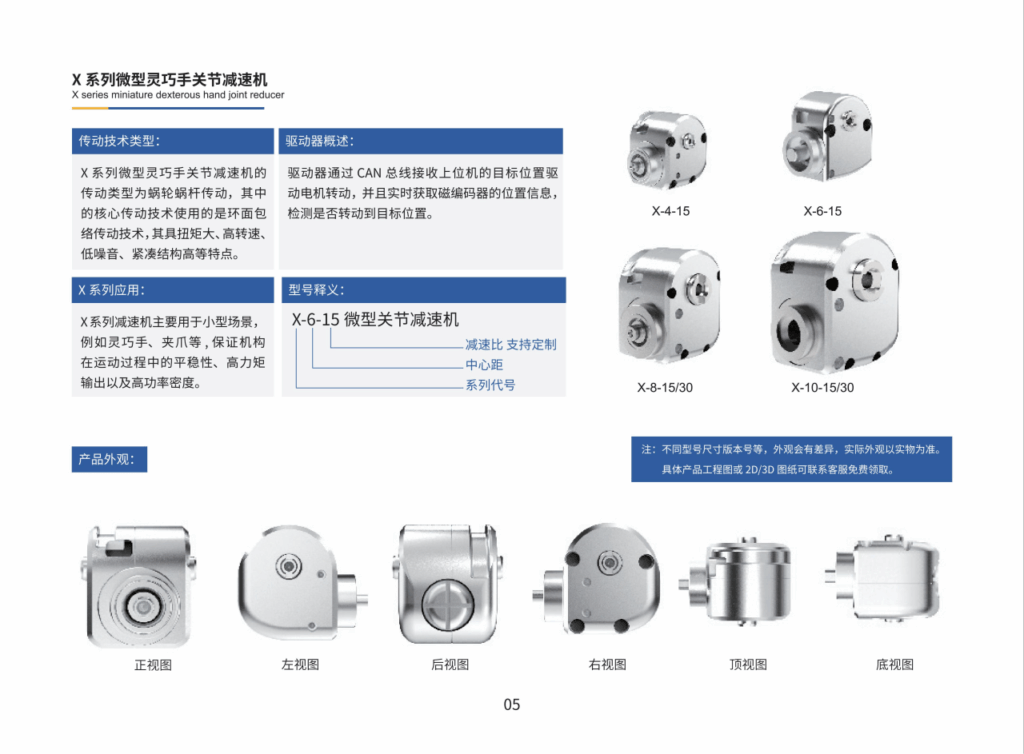

- In terms of volume, Taoshi ring surface envelope reducer, with its innate 90° orthogonal transmission structure, eliminates the need for additional steering device and makes the overall structure more compact. Taking the X series reducer applied in robot dexterous hand as an example, it weighs only 9-49 grams but can realize 1-3N-m torque output, which perfectly solves the transmission needs in space-constrained scenarios.

- In terms of economic benefits, the Tausch ring envelope reducer is comparable in price to traditional high-end corner reducers, but at a significantly lower overall cost of ownership. This is due to its higher transmission efficiency to bring energy savings, including the cost savings of no additional braking system, as well as longer service life to reduce the replacement and maintenance costs. Application data shows that the overall energy consumption can be reduced by 30%, bringing long-term economic benefits to users.

- The Taoshi Ring Surface Envelope Reducer has made a quantum leap in precision performance. The accuracy reaches ±0.5 arc minutes, while the operating noise is less than 50 dB.

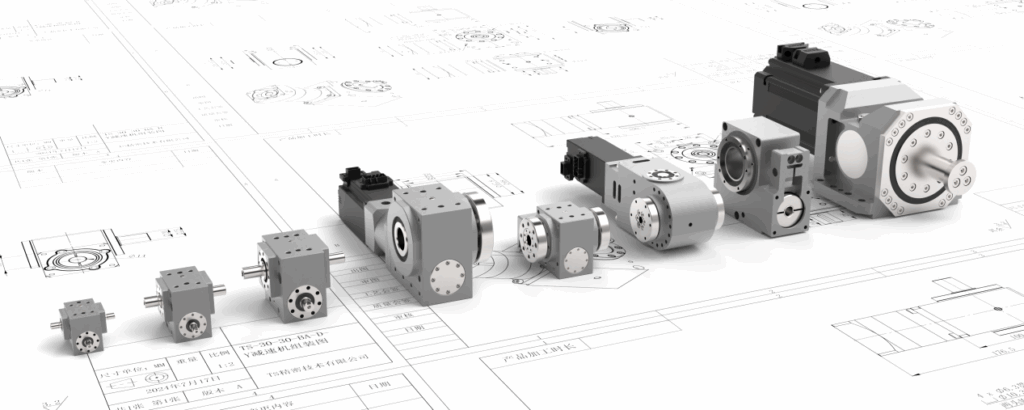

As industrial manufacturing advances further, the requirements for transmission components will become more and more demanding. The high torque density, high precision, low noise and long life Taoshi ring surface envelope reducer represents the direction of development in this field.

From precision medical devices to humanoid robots, this innovative product is proving its worth. With its superior technical features and significant cost advantages, it is rapidly gaining market share.

In the future, with the further maturation of the technology and the expansion of the industrialization scale, the ring surface envelope reducer is expected to replace the traditional corner reducer in more fields, and become the preferred solution in the field of precision transmission.

Taoshi Intelligent Technology

Taoshi Intelligent Technology